why edible oil refinery is necessary in kyrgyzstan

why edible oil refinery is necessary in sudan

Edible Oil Refinery Machine Manufacturer,Your Best Choice. Dec 05, 2024· Why Edible Oil Refinery Is Necessary. Edible oil is indispensable in our daily life, no matter what kind of food you make. Especially in China, we have accumulated thous of years diet culture, and edible oil quality will directly influence the food flavor. Thus high

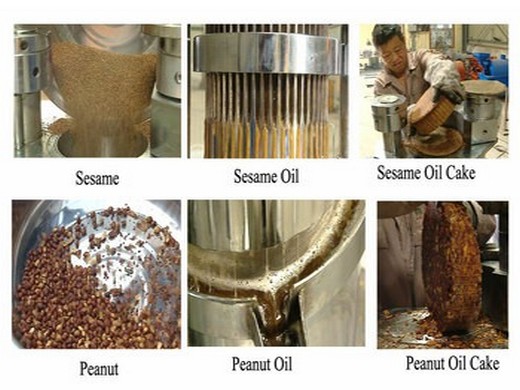

Edible oils which are used in our day to day life for the varied purpose are first refined in an oil refinery plant in order to remove unwanted compounds. Oil containing seeds are first expeller pressed for obtaining the crude edible oil. The oil cake left after the process of expeller pressing is further processed

Why crude edible oil should be refined?

Therefore, it is necessary to remove these useless matters based on different using requirements and make it edible. So, the crude edible oil needs to be refined for cooking or other edible purposes. Edible oil refinery process flow chart. Crude edible oil refining steps The typical steps in the crude edible oil refining process includes Degumming section, Neutralizing section, Decolorization

Edible oils are defined by the Government of Ontario, Canada as "a food substance, other than a dairy product, of whatever origin, source or composition that is manufactured for human consumption wholly or in part from a fat or oil other than that of milk." The US FDA does not provide a definition for edible oils on their website.

What aspects does influence edible oil refinery plant cost

There are several different aspects that influence the cost of Edible Oil Refinery Plant. A. Capacity B. Processing Quality C. Machinery Quality Capacity: Cost of Edible Oil Refinery Plant varies according to the capacity of the plant but there is...

Crude edible oil need refining in edible oil refinery plant. On the contrary, refined edible oil has a lot of advantages, such as more healthy, with longer storage time and with larger sale market. If you want to make your edible oil production business further development, you had better set up the edible oil refinery plant together.

Why does crude oil need to be further refined?

Crude palm oil extracted from palm oil pressing machine inevitably contains impurities. To make the standard edible palm oil, the impurities must be taken out; such a process is called “Refining” Oil refinery refers to a series of refining process...

Crude oil is a highly variable mixture of heavy and light hydrocarbons that need to be separated in a refinery. Discover why it needs to be Discover why it needs to be Refining Crude Oil for Use The gasoline or diesel we put in our car, the fuel oil we burn to heat our homes in winter and the natural gas we use to cook are all fuels and sources of heat derived from

Why Crude Palm Oil Refinery is Very Important Oil mill

Palm oil is one of the healthiest edible oils in the market today. This oil is mainly manufactured in most equatorial belts of the world with Indonesia and Malaysia being the world leading producers. This oil is not edible in its initial state and therefore the crude palm oil refinery is very important. Crude palm oil is dark in color before

After autoclaving, tissues of fish are pressed and the oil/water suspension is passed through centrifuges to separate the oil. Oil Refining. Refining produces an edible oil with characteristics that consumers desire such as bland flavour and odour, clear appearance, light colour, stability to oxidation and suitability for frying. Two main

Why Oil Refinery Is Important In Edible Oil Production

The edible oil that produced from the expeller is called crude oil; after the crude oil goes through the refinery process, it becomes the refined oil. Oil refinery is for the purpose of reducing the impurities and the toxic matters in the oil to make its shelf life longer.

Get Price

EDIBLE OILS AND FATS REFINING

REFINING The most frequent and important application of oily seeds and natural fats is by far in the field of edible products.Gianazza International has been active in the manufacture of edible oil refining plants for over one century and now it is engaged in the development of advanced

Get Price

edible oil refinery: Latest News & Videos, Photos about

edible oil refinery Latest Breaking News, Pictures, Videos, and Special Reports from The Economic Times. edible oil refinery Blogs, Comments and Archive News on Economictimes

Get Price

Basics of Alkali Refining of Vegetable Oils

Alkali Refining: General Comments A centrífuge or separator is an accelerator for the decantation of gums, soapstock or wash water from oil and is not changing anything in the chemical structure of the products. Important for the efficiency of the machines are the process conditions prior and during the separation (dosation

Get Price

Controlling quality in an edible oil refinery

Controlling quality in an edible oil refinery Inedible oil processing it must be accepted that the mw materials. being milural products. will vary with cli-mate, method of extraction. storage conditions. etc. Thus. application of fixed processing conditions will lead

Get Price

Alfa Laval Lube oil processing

Alfa Laval has the expertise, technology and services to meet refinery needs. Increasing energy efficiency in refinery lube oil processes. Whatever solvent is used to remove aromatic compounds and wax, several columns are needed to recover the solvent from extract, raffinate, wax and lube oil. To minimize the energy input to these evaporators

Get Price

Edible Oil Refinery Plant, Edible Oil Refinery, Edible Oil

We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants. Our machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, sunflower, soyabean, palm kernel, mustard, copra, sesame seed,

Get Price

EDIBLE OIL REFINERY, COOKING OIL REFINERY, REFINERY

Our edible oil refinery is ideally suitable to refine any kind of vegetable oil. We can supply edible oil refinery capacity 3 TPD to 30 TPD. We can supply edible oil refinery capacity 3 TPD to 30 TPD.

Get Price

Edible oil extraction machine manufacturer in Kazakhstan

Edible oil extraction machine is became more popular in the world. Because edible oil extraction machine can be used to process various kinds of oilseeds, such as soybean, peanut, cottonseed, rapeseed, sunflower seeds,mustard and so on. Reliable edible oil extraction machine manufacturer with good price and good service:

Get Price

The Detailed Information of Edible Oil Refining Process

It is very necessary that the edible oil refining process be known to the oil mill plants owner . The edible crude oil obtained from oil mill plants and solvent plants get refined in the vegetable oil refinery plants before it is utilized directly. The edible oil through the oil refining process gives color uniformity and appealing quality to

Get Price

Which one is the largest edible oil refinery in the World

Which one is the largest edible oil refinery in the World? UNANSWERED. We need you to answer this question! If you know the answer to this question, please register to join our limited beta

Get Price

Oil refinery

An oil refinery or petroleum refinery is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need

Get Price

Edible Oil Refinery Plant, Edible Oil Refinery Plant

Edible Oil Refinery Plant: Edible Oil Refinery: Edible Oil Refining Tinytech Udyog has been in the edible oil industry since 20 years. We are designers, manufacturers and global exporters of Edible Oil Refinery Plants for the refining of almost all kinds of crude oils.

Get Price

Physical refining process of edible oil, what is physical

It is necessary to choose the appropriate edible oil refining method according to the purpose of oil refining, taking into account technical conditions and economic benefits. In general,edible oil refining methods can be diovided into : Mechanical method, chemical method and physical and chemical method. Today we mainly introduce the physical refining method of edible oil.

Get Price

What is Oil Refinery and Edible Oil Refinery?

The edible oils are obtained from the likes of palm oil, soya bean oil, canola oil, corn germ oil, rape seed oil and others. In other words, the oil refinery process oil that cannot be consumed by human being while the edible oil refinery process oil that is edible (can be consumed by human beings).

Get Price

Offer Edible Oil Refinery Lines for Various Crude Oils

In fact, as a responsible supplier of edible oil refining machine, we are explicit that the EXACT cost of the edible oil refinery machine is decided by various aspects, including capacity, oil property, requirement for final produced oil, local market, etc. The Edible Oil Refining Plant Cost in small scale level ranges $21,000~$115,000.

Get Price

CODE OF PRACTICE FOR THE STORAGE AND TRANSPORT OF EDIBLE

when storing and transporting the oil. 2.1.1 Oxidation Contact of oils and fats with oxygen, present in the atmosphere, causes chemical changes in the product which downgrade the quality. Some of the effects of oxidation may be rectified within an edible oil refinery with some extra processing and, therefore, extra cost. However, the effects

Get Price

Edible Oil an overview ScienceDirect Topics

Edible Oil. Edible oil is a fatty liquid that is physically extracted from several vegetables and also some animal tissues, the most appreciated being olive oil for both taste and health properties (Preedy and Watson, 2010), especially the extra-virgin category, mechanically extracted from olives at

Get Price

Alfa Laval SoftColumn

The oil then proceeds to a final heater where it is brought up to the exact temperature required for deodorization, normally using high-pressure steam. Stripping and retention. When the oil has reached the designated temperature, it is fed to the deodorization column, which is the main component used for deodorizing edible fats and oils. Such a

Get Price

Edible Oil Refinery from Crude Palm Oil. Palm Oil

Crude Palm Oil (CPO) is one of the most important edible oil in India. Palm oil is one of the few vegetable oils known to be rather high in saturated fats, and it comes close to soybean oil as one of the most widely-produced vegetable oils in the world. Crude Palm Oil (palm fruit oil

Get Price

Edible Oil Refining Processes Degumming

The oil normally becomes cloudy in 5–6h but with proper dewaxing the oil remains clear after 24h of storage at 0˚C. The following steps are used to dewax sunflower oil: Crude oil is refined and bleached to low phosphorus (<1ppm) and low moisture content (<0.1%). The oil is heated to 55˚C to make sure the oil

Get Price

Vegetable oil Refinery Plant -Supplier & Manufacturers

Vegetable oil Refinery Plant is used to process this impure oil that is full of unhygienic components, odor and color. The foremost reason for refining this oil is to remove these fatty acids and prevent this oil from oxidation. However, our Vegetable oil Refinery Plant is not only using to refine this oil from fatty acids but also to neutralize, deodorize and bleach this oil to make it edible.

Get Price

Myanmar Edible Oil Seed Processing Industry Analysis

Myanmar is a significant producer of oil seed crops. Approximately 16 percent of the cultivated area or nearly 7.5 million acres of land are sown with oil crops, which is the third most important

Get Price

coconut oil refining process Edible Oil Refining Oil

Coconut Oil Refining Process The refined organic coconut oil is processed using the organically approved methods of physical extraction and refining. For the extraction step, the coconuts are broken into pieces and the coconut meat is allowed to dry, and once it is dried, the meat or flesh of the Coconut is hydraulically pressed at 100 130 degrees to extract the oil.

Get Price

Chlorophyll Removal From Edible Oils

Chlorophyll Removal From Edible Oils Int. J. Appl. Sci. Eng., 2005. 3, 2 83 deaerated oil, which was then heated under vacuum to the desired reaction temperature, with gentle mixing by a magnetic stirrer. The system was held at the reaction temperature for 10 to 60 min. then cooled to somewhat above ambient temperature under vacuum.

Get Price

1~5TPD Edible Oil Pressing Line Makes Oil

It is necessary to remove all the unhealthy and inedible substances. That is why our oil pressing plant is designed with Oil Filter Machine and Oil Refinery. 1~5TPD Edible Oil Pressing Line for Sales. Above processes are required for every edible oil processing line, no matter what capacity it is.

Get Price