palm oil mill effluent treatment through combined process adsorption and membrane filtration

Palm Oil Mill Effluent Treatment Through Combined Process

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration Muhammad Said1*, Siti Rozaimakh Sheikh Abdullah2, Abdul Wahab Mohammad 2 1 Department Of Chemistry, Fakultas Mathematics and Natural Sciences, University of Sriwijaya 2 Department Of Chemical and Process Engineering,

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration. Abstract: The growth in palm oil production also leads to an Increase in the production of palm oil mill effluent (POME). Nowadays, POME was treated using an open lagoon but this method is ineffectiveness in complying with the standards for water disposal.

Palm Oil Mill Effluent Treatment Through Combined Process

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration.pdf Available via license: CC BY-NC-SA 4.0 Content may be subject to copyright.

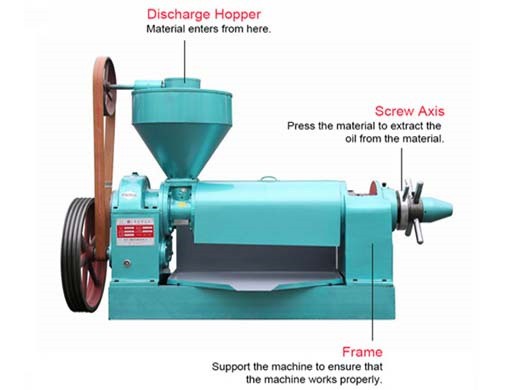

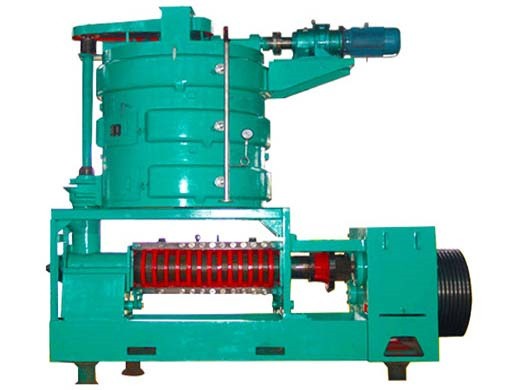

Jan 01, 2014· The application of membrane separation technology coupled with adsorption treatment (pre-treatment) can be effective means of treating palm oil mill effluent (POME).The pre-treatment process was done by stirring the raw palm oil mill effluent (POME) with 0.20 g/L of palm kernel shell-based activated carbon (PKS-AC) in 35.94 min with stirring speed 39.82 rpm and able to reduce

TREATMENT OF PALM OIL MILL EFFLUENT (POME) USING

Abd. Aziz et al: TREATMENT OF PALM OIL MILL EFFLUENT (POME) USING MEMBRANE BIOREACTOR 464 Introduction The history of palm oil can be traced back to the days of the Egyptian paraohs 5000 years B.C. It was introduced to Malaysia at the start of the 20th century and commercially produced in 1917. Palm oil's unique composition makes it

Combined magnetic field and adsorption process for treatment of biologically treated palm oil mill effluent (POME) Chem. Eng. J.,243 ( 2014 ),pp. 31 42 Article Download PDF View Record in

Optimization Of Palm Oil Mill Effluent Treatment

Ultrafiltration (UF) is one of the options for secondary treatment of palm oil mill effluent (POME). However, membrane fouling is still a major problem in this process.

Static magnetization is convenient, simple, of little cost, and may be an alternative by itself or to improve the adsorption. This paper aims to provide basic experimental findings of magnetic and magnetic assisted adsorption and to guide the application of the magnetic chemistry on adsorption process and palm oil mill effluent treatment. 2.

AN OVERVIEW OF GAS-UPGRADING TECHNOLOGIES FOR

Palm oil mill effluent (POME) is liquid waste generated from the oil-extraction process from fresh fruit bunches (FFBs) in palm oil mills [1], which originate from two main processes: (i) sterilization and (ii) clarification [2, 3]. POME consists of 95–96% water, 0.6–0.7% oil,

1. Introduction. At present, the palm oil mill industry is being dominated by the Southeast Asia region. Possessing to its suitability to regional climatic conditions and high yield rates, palm oil is the main biodiesel feedstock in Southeast Asia (Mukherjee and Sovacool, 2014).Since the 14th century it was introduced in this region, palm oil has become an important agricultural commodity

Palm Oil Mill Effluent Treatment Through Combined Process

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration . 0.5 bar trans-membrane pressure and 5 hours for filtration time. To predict COD removal, the results were analyzed by applying the artificial neural network (ANN) to derive a mathematical model

Get Price

Review on current approach for treatment of palm oil mill

Combined magnetic field and adsorption process for treatment of biologically treated palm oil mill effluent (POME) Chem. Eng. J.,243 ( 2014 ),pp. 31 42 Article Download PDF View Record in

Get Price

MODELING, SIMULATION AND DESIGN OF MEMBRANE

1.1 Palm Oil Mill Effluent (POME) 1 1.2 Environmental Regulatory Control for POME Discharge 3 1.3 Conventional Biological Treatment System for POME 4 1.4 Membrane based POME Treatment Pilot Plant 5 1.4.1 Coagulation and Flocculation Process 6 1.4.2 Sludge Dewatering by Using Filter Press 7

Get Price

Towards sustainable membrane filtration of palm oil mill

Oct 19, 2016· Amosa MK (2015a) Hybrid adsorption-membrane process for reclamation of bio-treated palm oil mill effluent for boiler-feed reuse. Ph.D. Thesis, International Islamic University Malaysia, Kuala Lumpur Amosa MK (2015b) Process optimization of Mn and H 2 S removals from POME using an enhanced empty fruit bunch (EFB)-based adsorbent produced by

Get Price

Principles and Mechanism of Adsorption for the Effective

Jan 01, 2024· Membrane separator technology was combined with adsorption treatment method for the treatment of POME (Azmi and Yunos, 2014), the adsorption process was used as pretreatment and was achieved by stirring the raw POME with 0.20 g/L of palm kernel shell-based activated carbon at a contact time of 35.94 minutes and agitation speed of 39.82 rpm

Get Price

AN OVERVIEW OF GAS-UPGRADING TECHNOLOGIES FOR

Palm oil mill effluent (POME) is liquid waste generated from the oil-extraction process from fresh fruit bunches (FFBs) in palm oil mills [1], which originate from two main processes: (i) sterilization and (ii) clarification [2, 3]. POME consists of 95–96% water, 0.6–0.7% oil,

Get Price

PRETREATMENT OF PALM OIL MILL EFFLUENT FOR WATER

Phenol Removal of Anaerobic Palm Oil Mill Effluent by Phanerochaetechrysosporim ATCC 24725. TIChE International conference. Wu, T.Y., Mohammad, A.W., Jahim, J.M. and Anuar, N. 2010. Pollution Control Technologies for the Treatment of Palm Oil Mill Effluent (POME) Through

Get Price

Performance of Composite Membrane for Palm Oil Wastewater

Palm Oil Mill Effluent Treatment through Combined Process Adsorption and Membrane Filtration. Memb. Water Treat. 5(3): 207-219. A. W. Zularisam, A. F. Ismail, M. R. Salim. 2006. Behavior of Natural Organic Matter (NOM) in Membrane Filtration for Surface Water Treatment: A Review. Desalination. 194(1-3): 211-231.

Get Price

Palm oil industry in South East Asia and the effluent

1. Introduction. At present, the palm oil mill industry is being dominated by the Southeast Asia region. Possessing to its suitability to regional climatic conditions and high yield rates, palm oil is the main biodiesel feedstock in Southeast Asia (Mukherjee and Sovacool, 2014).Since the 14th century it was introduced in this region, palm oil has become an important agricultural commodity

Get Price

The Optimization of the Electrocoagulation of Palm Oil

Jan 28, 2024· The Combination of Air Flotation and a Membrane Bioreactor for the Treatment of Palm Oil Mill Effluent. International Journal of Technology, Volume 7(5), pp. 567–777. Kuokkanen, V., Kuokkanen, T., Ramo, J., Lassi, U., 2013. Recent Applications of Electrocoagulation in Treatment of Water and Wastewater -A Review.

Get Price

Membrane treatment for palm oil mill effluent

Membrane treatment for palm oil mill effluent: Effect of transmembrane pressure and crossflow velocity The supernatant from the sedimentation process was then fed through a fixed bed of activated carbon for the adsorption process. Granular activated carbon from palm kernel shells with a mesh size of 8×30 was packed inside a perspex column

Get Price

Ultrafiltration of palm oil mill effluent: Effects of

is assumed that for production of 1 tonne crude palm oil, amount of water used is 5-7.5 tonnes and half of the water used will end up as palm oil mill effluent (POME) [1-2]. Raw POME undergoes series of treatment such as biological treatment, anaerobic treatment and ponding system process before discharged to the river [3].

Get Price

Tertiary Treatment of Biologically Treated Palm Oil Mill

The production of palm oil generates wastes that are of great concern to the environment. The process of palm oil mill production consumes large amount of water and 50 % of it ends up as palm oil mill effluent (POME). POME is a highly colloidal suspension of 95-96 % water, 0.6-0.7 % oil

Get Price

Thermo responsive antifouling study of commercial PolyCera

the antifouling function of the membrane in palm oil mill effluent (POME) treatment. The evaluation of the membrane’s thermo-responsive ability was done through three cycles of adsorption (fouling) and desorption (defouling) processes in a membrane filtration process.

Get Price

Palm Oil Mill Effluent Treatment Through Combined Process

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration . 0.5 bar trans-membrane pressure and 5 hours for filtration time. To predict COD removal, the results were analyzed by applying the artificial neural network (ANN) to derive a mathematical model

Get Price

MODELING, SIMULATION AND DESIGN OF MEMBRANE

1.1 Palm Oil Mill Effluent (POME) 1 1.2 Environmental Regulatory Control for POME Discharge 3 1.3 Conventional Biological Treatment System for POME 4 1.4 Membrane based POME Treatment Pilot Plant 5 1.4.1 Coagulation and Flocculation Process 6 1.4.2 Sludge Dewatering by Using Filter Press 7

Get Price

Membrane treatment for palm oil mill effluent

Membrane treatment for palm oil mill effluent: Effect of transmembrane pressure and crossflow velocity The supernatant from the sedimentation process was then fed through a fixed bed of activated carbon for the adsorption process. Granular activated carbon from palm kernel shells with a mesh size of 8×30 was packed inside a perspex column

Get Price

Palm Oil Effluent Treatment with VSEP

effluent generated during the production of palm oil. The company using the technology operates three palm oil mills in Guatemala. The VSEP system was installed at the company’s new facility in Mexico near the border between Mexico and Guatemala. The three existing mills and the new mill can process sixty tons of oil per hour.

Get Price

Water recycling from palm oil mill effluent (POME

It is estimated that for 1 tonne of crude palm oil produced, 5-7.5 tonnes of water are required, and more than 50% of the water will end up as palm oil mill effluent (POME). Thus, while enjoying a most profitable commodity, the adverse environmental impact from the palm oil industry cannot be ignored.

Get Price

PRETREATMENT OF PALM OIL MILL EFFLUENT FOR WATER

Phenol Removal of Anaerobic Palm Oil Mill Effluent by Phanerochaetechrysosporim ATCC 24725. TIChE International conference. Wu, T.Y., Mohammad, A.W., Jahim, J.M. and Anuar, N. 2010. Pollution Control Technologies for the Treatment of Palm Oil Mill Effluent (POME) Through

Get Price

The Optimization of the Electrocoagulation of Palm Oil

Jan 28, 2024· The Combination of Air Flotation and a Membrane Bioreactor for the Treatment of Palm Oil Mill Effluent. International Journal of Technology, Volume 7(5), pp. 567–777. Kuokkanen, V., Kuokkanen, T., Ramo, J., Lassi, U., 2013. Recent Applications of Electrocoagulation in Treatment of Water and Wastewater -A Review.

Get Price

Journal of Oil Palm, Environment & Health

sequestration and integrated membrane filtration treatment processes in recovering treated water for boiler feed application. On the tonnes of palm oil mill effluent (POME) and 0.37 tonnes of solid waste are generated. The composting in the oil palm plantation, the degradation process

Get Price

Integrated Adsorption–Coagulation and Naofiltration of

single step using adsorption-coagulation. Asadullah and Rathnasiri (2015) treated palm oil effluent using adsorption-coagulation method and also stated that separate adsorption or coagulation process is not the effective method for effluent treatment but a combined coagulation-adsorption processes are the most effective one.

Get Price

Thermo responsive antifouling study of commercial PolyCera

the antifouling function of the membrane in palm oil mill effluent (POME) treatment. The evaluation of the membrane’s thermo-responsive ability was done through three cycles of adsorption (fouling) and desorption (defouling) processes in a membrane filtration process.

Get Price

Tertiary Treatment of Biologically Treated Palm Oil Mill

The production of palm oil generates wastes that are of great concern to the environment. The process of palm oil mill production consumes large amount of water and 50 % of it ends up as palm oil mill effluent (POME). POME is a highly colloidal suspension of 95-96 % water, 0.6-0.7 % oil

Get Price

Performance of BioFouling Reducers in Aerobic

Ahmad, A.L., Ismail, S. and Bhatia, S. (2005) Membrane treatment for palm oil mill effluent: effect of transmembrane pressure and crossflow velocity. Desalination 179:245-255. 11 [3] Ma, A.N. (2000) Environmental management for the palm oil industry. Palm Oil Developments 30:1-10. [4]

Get Price

Palm Oil Mill Effluent Treatment Through Combined Process

Palm Oil Mill Effluent Treatment Through Combined Process Adsorption and Membrane Filtration . 0.5 bar trans-membrane pressure and 5 hours for filtration time. To predict COD removal, the results were analyzed by applying the artificial neural network (ANN) to derive a mathematical model

Get Price