experimental study of palm oil press machine mill effluent

Palm oil mill effluent Feedipedia

Palm oil mill effluent is the voluminous liquid waste that comes from the sterilisation and clarification processes in milling oil palm. The raw effluent contains 90-95% water and includes residual oil, soil particles and suspended solids.

Optimised Treatment of Palm Oil Mill Effluent Article (Available) in International Journal of Environment and Waste Management 3(3/4):265-277 · January

Experimental study of palm oil mill effluent and oil

Experimental study of palm oil mill effluent and oil palm frond waste mixture as an alternative biomass fuel Article (Available) in Journal of Engineering Science and Technology 8(6):703-712

EXPERIMENTAL STUDY OF PALM OIL MILL EFFLUENT AND OIL PALM. Experimental Study of Palm Oil Mill Effluent and Oil Palm frond Waste Mixture 705 Journal of Engineering Science and Technology December 2013, Vol. 8(6) with a pH between 4 to 5, Parveen et al. [3]. POME is a non-toxic waste, as no. Get Price

EXPERIMENTAL STUDY OF PALM OIL MILL EFFLUENT AND OIL

Experimental Study of Palm Oil Mill Effluent and Oil Palm frond Waste Mixture 705 Journal of Engineering Science and Technology December 2013, Vol. 8(6) with a pH between 4 to 5, Parveen et al. [3]. POME is a non-toxic waste, as no chemical is added during the oil

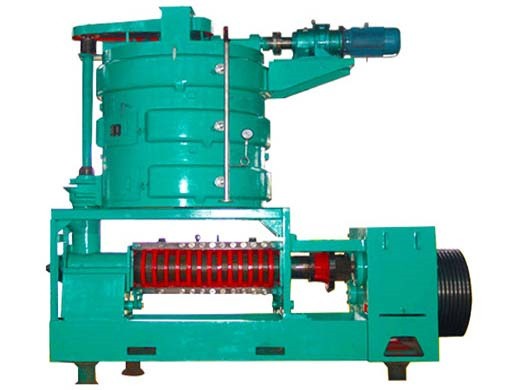

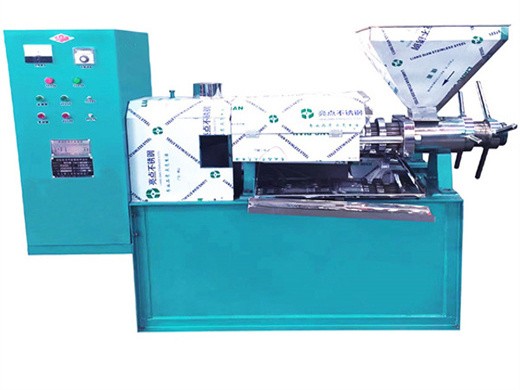

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

Palm oil mill process Palm oil extraction machine

5. Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the

A rattan palm is a type of climbing vine that is native to southeast Asia. There are over 300 known species of this strong, flexible, and fast growing palm.Some varieties of rattan palms are fruit bearing and can grow to nearly 600 feet (180 m) in length.

How to deal with palm oil mill effluent(1)?_Manufacture

According to statistical datum, producing 1ton crude palm oil will generate 0.5tons water water, for a 100t/d palm oil mill factory, it means it will produce 50tons palm oil mill effluent at least.waste. The waste water is brown with the oil and impurities, water temperature is about 80-90℃, Ph4-5, it is with some oil, metal, organic

EXPERIMENTAL STUDY OF PALM OIL MILL EFFLUENT AND OIL PALM . Experimental Study of Palm Oil Mill Effluent and Oil Palm frond Waste Mixture 705 Journal of Engineering Science and Technology December 2013, Vol. 8(6) with a pH between 4 to 5, Parveen et al. [3].

A Review of Palm Oil Mill Effluent (Pome) Water Treatment

Specifically, palm oil mill effluent (POME), is a to assess a more economical method of running a palm general phrase referring to the effluent from the final oil clarification plant [2] and utilizing the effluent water stages of palm oil production in the mill. It includes or converting it

Get Price

Studies on the Pre-Treatment of Palm Oil Mill Effluent

Studies on the Pre-Treatment of Palm Oil Mill Effluent Florence Wong Pin Sing This thesis is presented for the Degree of Master of Philosophy of Curtin University January 2012 . Declaration “To the best of my knowledge and belief this thesis contains no material previously published by any other person except where due acknowledgment has been made. This thesis contains no material which has

Get Price

Degradation behavior of palm oil mill effluent in Fenton

An in-depth study on degradation behavior of palm oil mill effluent (POME) in Fenton oxidation was accomplished with complete carbon and nitrogen balances. Experiments were conducted for real POME with a pH range of 2–5. POME contained high COD (50,000

Get Price

pH 0 THE STUDY ON BIOLOGICAL PH TREATMENT OF ACIDIC PALM

2.4 Experimental Setup In this study, inoculum was mixed with palm oil mill effluent (POME) in ratio of 1:3 (50 mL inoculum and 150 mL POME). Then the mixture was placed in incubator shaker. The experiments were carried out under anaerobic condition. The experimental table was designed and constructed using response surface

Get Price

PREPARATION OF BIOCHAR WITH PALM OIL MILL SLUDGE

PREPARATION OF BIOCHAR WITH PALM OIL MILL SLUDGE BY USING MICROWAVE FOR COPPER REMOVAL ABSTRACT This study aims to prepare the bio-char from residues of palm oil mill sludge (POMS) after anaerobic digestion system through microwave pyrolysis method to remove copper. The two main parameters i.e. temperature, and holding time for the bio-char

Get Price

Bio-hydrogen production from palm oil mill effluent

Raw palm oil mill effluent (POME) from a cooling pond and sludge from anaerobic pond of the POME treatment plant at Labu palm oil mill were collected for the study. The treatment of POME was carried out under anaerobic fermentation process, with an objective to produce bio-hydrogen via microflora. The experiments were conducted in 500 mL

Get Price

EVALUATING CAPACITY OF PALM OIL MILL USING SIMULATION

fruit bunches to the mill. Field of Research: Capacity, Simulation, Downtime, Supply chain, Palm oil mill 1. INTRODUCTION Malaysia is among the top leaders in palm oil industry to the world. As the main exporter to the world, providing the effective supply chain is needed. Supply chain of palm oil begins from the estate or plantation to the

Get Price

POME What is it? Indo Energy

POME: WHAT IS IT? January 2015. What is Palm Oil Mill Effluent? There is often confusion around the terminology used in the palm oil industry, with some definitions having significant meaning in relation to sustainability criteria. Unfortunately some of the terminology being used leads to confusion and misunderstanding. This document is an attempt to explain the differences with respect to the

Get Price

Microwave Drying of Palm Oil Mill Effluent

The experimental results clearly showed that microwave drying can be considered as an alternative technique for the POME treatment since it is efficient, quick and does not pollute the environment. Keywords: microwave drying, pennittivity, palm oil mill effluent INTRODUCTION Palm oil mill effluent (POME) is a liquid waste from palm oil mills which

Get Price

POME What is it? Indo Energy

POME: WHAT IS IT? January 2015. What is Palm Oil Mill Effluent? There is often confusion around the terminology used in the palm oil industry, with some definitions having significant meaning in relation to sustainability criteria. Unfortunately some of the terminology being used leads to confusion and misunderstanding. This document is an attempt to explain the differences with respect to the

Get Price

REGENERATE OF DECANTER CAKE FROM PALM OIL MILL WASTE

palm oil production also called Palm Oil l Effluent (POME). Mil Besides that, the palm oil industry also generates large amount of palm shell, a large portion of it is either burned in the open air or was dumped in adjacent area to be mill, which contribute environmental and disposal problem within near areas. The one of the palm oil mill waste

Get Price

ZERO DISCHARGE TREATMENT TECHNOLOGY OF PALM OIL MILL EFFLUENT

ZERO DISCHARGE TREATMENT TECHNOLOGY OF PALM OIL MILL EFFLUENT SOH KHEANG LOH*; MEI EE LAI*; MUZZAMMIL NGATIMAN*; WENG SOON LIM*; YUEN MAY CHOO*; ZHENJIA ZHANG** and JUMAT SALIMON‡ Journal of Oil Palm Research Vol. 25 (3) December 2013 p. 273-281 RESEARCH ARTICLES ABSTRACT Palm oil processing operation is invariably accompanied by palm oil mill effluent

Get Price

Improved Anaerobic Treatment of Palm Oil Mill Effluent

The export earnings from palm oil, palm kernel oil, and its products in 1998 amounted to almost US$5.6 billion, equivalent to 5.6% of the country’s GDP. Today, Malaysia is the world’s largest producer and exporter of palm oil (Yusoff, 2006). However, despite the high economic returns, the generation of liquid waste or palm oil mill effluent

Get Price

Biodegradation of palm oil mill effluent (POME) by bacterial.

he palm oil industry is one of the major agro-industries in Malaysia. The production of palm oil, however, results in the generation of large quantities of polluted wastewater commonly referred to as palm oil mill effluent (POME). The most significant pollutant from palm oil mils is POME (Poh and Chong, 2009). Typically, 1 t of crude palm oil

Get Price

Pre-Treatment Effect of Palm Oil Mill Effluent (POME

experimental studies were done in non sterile condition. The best result obtain will run in 2L fermenter with pH controller. II. MATERIAL AND METHODS A. Palm oil mill effluent (POME) POME was collected from Sri Langat palm oil mill, Dengkil, Selangor. The collected POME was

Get Price

Zero Discharge Performance of an Industrial Pilot-Scale

Palm oil is one of the most important agroindustries in Malaysia. Huge quantities of palm oil mill effluent (POME) pose a great threat to aqueous environment due to its very high COD. To make full use of discharged wastes, the integrated “zero discharge” pilot-scale industrial plant comprising

Get Price

Enhancement of Biodegradation of Palm Oil Mill Effluents

This study was designed to investigate the microorganisms associated with palm oil mill effluent (POME) in Johor Bahru state, Malaysia. Biodegradation of palm oil mill effluents (POME) was conducted to measure the discarded POME based on physicochemical quality. The bacteria that were isolated are Micrococcus species, Bacillus species, Pseudomonas species, and Staphylococcus

Get Price

ENHANCING OF METHANE PRODUCTION FROM PALM OIL MILL

Keywords- Biogas, Methane, Wastewater, Palm Oil Mill Effluent (POME), Palm Oil Fruit Bunch (EFB) I. INTRODUCTION The palm oil industry is an important industry in southern Thailand due to this region is the main area of oil palm plantations. The palm oil process

Get Price

Production of palm oil from fruit SpringerLink

Abstract. Palm oil is obtained from the fruit flesh ofElaeas guineensis.Whole bunches of ripe fruit are harvested and brought to the oil mill. Processing involves sterilization, mechanical removal of fruit from the bunch, and mechanical breakdown of the fruit structure followed by expression of the oil in a screw press.

Get Price

REGENERATED SPENT BLEACHING EARTH FOR THE DECOLOURISATION

REGENERATED SPENT BLEACHING EARTH FOR THE DECOLOURISATION AND BOD REDUCTION OF PALM OIL MILL EFFLUENT RUSNANI ABD MAJID* and CHE RAHMAT CHE MAT* ABSTRACT The aim of the present study is to evaluate the possibility of re-using the regenerated spent bleaching earth, subjected to acid and heat treatment, to decolourise and reduce the biological oxygen demand (BOD) of the final effluent

Get Price

Microwave Drying of Palm Oil Mill Effluent Universiti

This paper describes the treatment of palm oil mill effluent (POME) by using microwave drying. The study concentrated on the variation of the drying rate with respect to different initial mass and microwave power and the effect of silicon carbide (SiC) to enhance the drying. The initial mass of sample and energy level ranges from 20. 50 g and 91 504 watt respectively.

Get Price

ACTIVATED CARBON FROM OIL PALM BIOMASS AS POTENTIAL

ACTIVATED CARBON FROM OIL PALM BIOMASS AS POTENTIAL ADSORBENT FOR PALM OIL MILL EFFLUENT TREATMENT INTRODUCTION In palm oil milling, about 5%-7% palm kernel shell (PKS), 21%-22% empty fruit bunch (EFB) and 12%-16% mesocarp fibre (MF) are generated from each tonne of fresh fruit bunch (FFB) processed (Loh, 2016). In 2015, the Malaysian palm oil

Get Price

Bio-Optimization of Chemical Parameters and Earthworm

The present study reports mathematical modelling of palm oil mill effluent and palm-pressed fiber mixtures (0% to 100%) during vermicomposting process. The effects of different mixtures with respect to pH, C:N ratio and earthworms have been optimized using the

Get Price

6. ENVIRONMENTAL CONSIDERATIONS

In a well run palm oil mill, it is expected that each 100 tonnes of FFB processed yields 20 to 24 tonnes of crude palm oil and about 4 tonnes of palm kernels. Thus between 72 to 76 percent of the FFB comes out at various stages of the process as waste. The solid wastes that result from the milling

Get Price

Potential of biogas production from palm oil mills

In Nigeria, several kiloliters/tonnes of palm oil mill effluent (POME) are produced during processing of crude palm oil. This study evaluated the potential of biogas production from POME that is being discharged into the environment without treatment. Historical study period of this paper remained from 2004 to 2013. Palm oil production data and literature on biogas production using different

Get Price

Greenhouse gas reductions through enhanced use of residues

achieved by optimizing the use of residues in the life cycle of palm oil derived biodiesel. This is done through compilation of data on existing and treatment prospective technologies as well as practical experiments on methane potentials from empty fruit bunches. Methane capture from the anaerobic digestion of palm oil mill effluent was

Get Price

BioMed Research International Hindawi

Palm oil is one of the most important agroindustries in Malaysia. Huge quantities of palm oil mill effluent (POME) pose a great threat to aqueous environment due to its very high COD. To make full use of discharged wastes, the integrated “zero discharge” pilot-scale industrial plant comprising “pretreatment-anaerobic and aerobic process-membrane separation” was continuously

Get Price