Liberia soybean oil solvent extraction

Solvent extraction process of soybean Edible Oil

Aug 09, 2024· Solvent extraction of soybean . Basic principles and elements of solvent extraction; Oil extraction is to extract the oil from the embryo by wetting and infiltration, molecular diffusion and convective diffusion with solvent which can dissolve the oil. The mixture of solvent and fat is then separated to recover the solvent to obtain the crude oil.

Buy Best selling soybean oil solvent extraction plant oil cake solvent extraction machine solvent extraction from Microwave dryer dehydration sterilization machine,solvent extraction machine Distributor online Service suppliers.

Soybean Oil Extraction Plant Technical Process

Solvent extraction process To remove any soybeans oil which remains during extrusion process highly volatile hydrocarbon is used. This solvent normally hexane absorbs any oil remaining in the seeds. Later the oil is acquired when the solvent evaporates due to its volatile nature. Refining the extracted oil. The oil extracted is normally not

Soybean oil is also used as a feedstock for biodiesel production. Measurement of extracted oil in hexane for extraction process optimization The oil from soybeans is extracted using commercial hexane in solvent extraction. Up to 90% of the solvent remaining in the extracted oil evaporates and is then collected for reuse.

Solvent extraction process of soybean Edible Oil

Solvent extraction of soybean . Basic principles and elements of solvent extraction; Oil extraction is to extract the oil from the embryo by wetting and infiltration, molecular diffusion and convective diffusion with solvent which can dissolve the oil. The mixture of solvent and fat is then separated to recover the solvent to obtain the crude oil.

solvent extraction systems remove 10«6 pounds, or 20*5 per cent more. Since crude soybean oil sells for about five times aa much aa soybean meal, the advantage of solvent extraction (assaming eg[ual processing costs} is obvioaa. A characteristic of soybeans greatly aiding the solvent

Soybean oil production Vaisala

Soybean oil is also used as a feedstock for biodiesel production. Measurement of extracted oil in hexane for extraction process optimization The oil from soybeans is extracted using commercial hexane in solvent extraction. Up to 90% of the solvent remaining in the extracted oil evaporates and is then collected for reuse.

The extraction of soy oil from soybean flakes in industry requires large amounts of hexane solvent and results in significant losses and energy consumption during the distillative removal of the solvent.Hexanes and related hydrocarbon extractants are also becoming an environmental and health concern. A new method for extraction of the oil is sought, that would require neither hexane nor

Soybean Oil Extraction Plant Technical Process

Solvent extraction process To remove any soybeans oil which remains during extrusion process highly volatile hydrocarbon is used. This solvent normally hexane absorbs any oil remaining in the seeds. Later the oil is acquired when the solvent evaporates due to its volatile nature. Refining the extracted oil. The oil extracted is normally not

The main aim of this work was to obtain experimental data of the extraction kinetics of soybean oil and free fatty acids (FFA) for systems containing an expanded mass of soybean (collets) and ethanol with different hydration levels (0 and 5.98 mass% of water) at temperatures of 40, 50 and 60 °C.Through the obtained experimental data it can be seen that increasing the hydration level

9.11.1 Vegetable Oil Processing

Solvent Extraction and Oil Desolventizing The extraction process consists of "washing" the oil from the soybean flakes with hexane solvent in a countercurrent extractor. Then the solvent is evaporated (i. e., desolventized) from both the solvent/oil mixture (micella) and the solvent-laden, defatted flakes (see Figure 9.11.1-3). The oil is

Get Price

Soybean Processing Crown Iron Works

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the equipment.

Get Price

Sustainability analysis of soybean refinery: soybean oil

Figure 4-1 Soybean oil hexane extraction TEA model.. 54 . Figure 4-2 Power relationship between total capital investment and different . scales of soybean oil extraction .. 62 .

Get Price

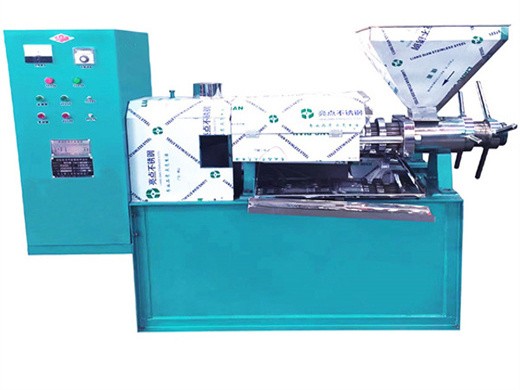

Soybean oil refinery machine Oil Extraction

No matter the crude soybean oil is get by oil press or oil solvent extraction way, it can be refined by the soybean oil refinery machine. The main purpose of soybean oil refinery machine is to separate the impurities in the crude soybean oil based on the different characteristics and enhance the stability and purity of oil. Soybean oil refinery machine includes two technologies, physical

Get Price

Extraction of oil from soybeans SpringerLink

Modern processing plants extract soyabean oil by solvent liquid transfer. Soyabeans are cleaned, cracked, dehulled and conditioned into a thin flake before they enter the extractor. Extraction is by successive, countercurrent washes of hexane solvent. The extracted flakes are then carried by a sealed conveyor to be desolventized in enclosed vessels by application of jacket and sparge steam.

Get Price

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil. The solvent is used for recycling and soybean crude oil is refined by oil

Get Price

How to make soybean oil? How to choose soybean oil

The soybean oil solvent extraction production line is suitable for soybean oil extraction plants with large capacity. If your processing capacity is above 30 tons per day, the soybean oil solvent extraction production line is your best choice. Extracting soybean oil by solvent extraction method, the residual oil rate of the cake is less than 1%

Get Price

Commercial extraction of soybean oil using non

solvent extraction systems remove 10«6 pounds, or 20*5 per cent more. Since crude soybean oil sells for about five times aa much aa soybean meal, the advantage of solvent extraction (assaming eg[ual processing costs} is obvioaa. A characteristic of soybeans greatly aiding the solvent

Get Price

Soybean Processing Crown Iron Works

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the equipment.

Get Price

Soybean Oil Extraction Plant Technical Process

Solvent extraction process To remove any soybeans oil which remains during extrusion process highly volatile hydrocarbon is used. This solvent normally hexane absorbs any oil remaining in the seeds. Later the oil is acquired when the solvent evaporates due to its volatile nature. Refining the extracted oil. The oil extracted is normally not

Get Price

9.11.1 Vegetable Oil Processing

Solvent Extraction and Oil Desolventizing The extraction process consists of "washing" the oil from the soybean flakes with hexane solvent in a countercurrent extractor. Then the solvent is evaporated (i. e., desolventized) from both the solvent/oil mixture (micella) and the solvent-laden, defatted flakes (see Figure 9.11.1-3). The oil is

Get Price

Ethanol extraction of soybean oil Arnold 1962

Extraction of soybean flakes with 90, 95, 98 and 100% ethanol resulted in more rapid lipid and less rapid non‐lipid removal with the increasing ethanol concentrations. There was little difference in the quality of the oil produced by the different solvents. Protein content of the residual meal averaged 52.1%.

Get Price

Sustainability analysis of soybean refinery: soybean oil

Figure 4-1 Soybean oil hexane extraction TEA model.. 54 . Figure 4-2 Power relationship between total capital investment and different . scales of soybean oil extraction .. 62 .

Get Price

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil. The solvent is used for recycling and soybean crude oil is refined by oil

Get Price

Professional Process of Soybean Oil Production

The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then further purified. Solvent Extraction Workshop View: Purification Section of Soybean Oil Production: The crude soybean oil still contains many oil-insoluble and oil

Get Price

soybean oil solvent extraction plant with the best quality

Soybean oil solvent extraction plant Edible oil extraction. The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm

Get Price

How to make soybean oil? How to choose soybean oil

The soybean oil solvent extraction production line is suitable for soybean oil extraction plants with large capacity. If your processing capacity is above 30 tons per day, the soybean oil solvent extraction production line is your best choice. Extracting soybean oil by solvent extraction method, the residual oil rate of the cake is less than 1%

Get Price

Technology of production of edible flours and protein

Despite considerable research efforts to develop alternative solvent systems, extraction with light hydrocarbons continues to be, practically, the only commercial solvent extraction process for soybean oil. c- Types of extractors: Solvent extractors are of three types: batch, semi-continuous and continuous.

Get Price

Deacidification of Soybean Oil Combining Solvent

The aim of this work was to study the removal of free fatty acids (FFAs) from soybean oil, combining solvent extraction (liquid-liquid) for the separation of FFAs from the oil and membrane technology to recover the solvent through nanofiltration (NF). Degummed soybean oil containing 1.05 ± 0.10% w/w FFAs was deacidified by extraction with ethanol.

Get Price

Manufacturer, supplier of Soybean oil solvent extraction

The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola

Get Price

How to use solvent extraction process to make soybean oil

Using solvent extraction process to make soybean oil is very popular. If you want to manufacture soybean oil by solvent extraction method, the input capacity of soybeans each day had better more than 30 tons, for the cost of soybean oil solvent extraction machine is higher than soybean oil

Get Price

9.11.1 Vegetable Oil Processing

Solvent Extraction and Oil Desolventizing The extraction process consists of "washing" the oil from the soybean flakes with hexane solvent in a countercurrent extractor. Then the solvent is evaporated (i. e., desolventized) from both the solvent/oil mixture (micella) and the solvent-laden, defatted flakes (see Figure 9.11.1-3). The oil is

Get Price

Research Article Deacidification of Soybean Oil Combining

Deacidification of Soybean Oil Combining Solvent Extraction and Membrane Technology M.L.Fornasero, 1 R.N.Marenchino, 1 andC.L.Pagliero 1,2

Get Price

Sustainability analysis of soybean refinery: soybean oil

Figure 4-1 Soybean oil hexane extraction TEA model.. 54 . Figure 4-2 Power relationship between total capital investment and different . scales of soybean oil extraction .. 62 .

Get Price

Deacidification of Soybean Oil Combining Solvent

The aim of this work was to study the removal of free fatty acids (FFAs) from soybean oil, combining solvent extraction (liquid-liquid) for the separation of FFAs from the oil and membrane technology to recover the solvent through nanofiltration (NF). Degummed soybean oil containing 1.05 ± 0.10% w/w FFAs was deacidified by extraction with ethanol.

Get Price

Emission Estimation Technique Manual

2.1.3 Solvent Extraction and Oil Desolventising The extraction process consists of “washing” the oil from the soybean flakes with hexane solvent in a countercurrent extractor. The solvent is then evaporated (ie. desolventised) from both the solvent/oil mixture (micella) and the solvent-laden defatted flakes (see Figure 4).

Get Price

Solvent extraction for heavy crude oil removal

A new strategy of heavy crude oil removal from contaminated soils was studied. The hexane-acetone solvent mixture was used to investigate the ability of solvent extraction technique for cleaning up soils under various extraction conditions. The mixtures of hexane and acetone (25 vol%) were demonstra

Get Price

VEGETABLE OILS AS A SOLVENT FOR THE LIQUID LIQUID

Fig 6 : Graph for Soybean Oil Conclusions. From the tables it is evident that sunflower oil, ricebran oil, groundnut oil and soybean oil can be used as a solvent for the extraction of isopropanol from isopropanol water mixture. Equilibrium data has been generated for isopropanol, water and vegetable oil ternary systems at room

Get Price

soybean oil solvent extraction plant with the best quality

Soybean oil solvent extraction plant Edible oil extraction. The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm

Get Price