basics of alkali refining of vegetable oils

Basics of Alkali Refining of Vegetable Oils

Basics of Alkali Refining of Vegetable Oils Renato Dorsa Klaus-Peter Eickhoff Mechanical Separation Division Westfalia Separator Food Tec GmbH. 2 Objectives of Refining 1. Removal of undesired products from crude oils • free fatty acids (FFA) • phospholipids (gums) • oxidised products • metal ions • colour pigments • others 2. Preservation of valuable vitamínes. (vitamina E or

Physical refining is a process making use of the lower boiling point of the FFA compared to the boiling point of the triglyceride oil. In chemical or alkaline refining, an alkali is used to neutralise the FFA. Figure 1. Chemical and physical refining. Chemical refining is the traditional method used in past centuries. The main purpose

Vegetable Oil Refinery, Oil Refining Plant, Oil Refining

In Chemical Refining, Vegetable Oil is treated with caustic lye for separation of free fatty acids from oil. This is a conventional process that can be applied to all oils. A byproduct of alkali refining is soap-stock, which is used for manufacture of low quality washing soap. Alternately, the soap-stock can be treated with acid to recover fatty acids. The waste-water from refinery requires

Basics of Alkali Refining of Vegetable Oils. Basics of Alkali Refining of Vegetable Oils Renato Dorsa Klaus-Peter Eickhoff Mechanical Separation Division Westfalia Separator Food Tec GmbH. 2 Objectives of Refining 1. Removal of undesired products from crude oils Physical Refining: Removal by distillation at higher temperature and low vacuum. 5

EDIBLE OILS AND FATS REFINING

the oil, it is actually a refining step that removes many impurities, mainly soaps remained in the oil after alkali refining and phosphatides. Fully continuous plants are available for capacities of 25 t/d upwards: the operation is rigorously continuous in the bleaching step proper, while filtration is semi-continuous in the sense that there

Alkali refining of oil is compulsory in crude oils of high acidity and pigment contents. The free fatty acid content of the oil is the main factor that determines the amount and concentration of the caustic soda and also its excess (5 to 20%) for a minimum oil loss.

Chapter 5 : Processing and refining edible oils

A prerequisite for physical refining is that phosphatides be removed to a level below 5 mg phosphorus/kg oil. In the classic refining process, this level is easily achieved during the neutralisation stage, but special degumming processes may be required for physical refining of high-phosphatide seed oils. These procedures rely on improved

Alkali refining of oil is compulsory in crude oils of high acidity and pigment contents. The free fatty acid content of the oil is the main factor that determines the amount and concentration of the caustic soda and also its excess (5 to 20%) for a minimum oil loss.

Advanced Vegetable Oil Processing and Its Steps

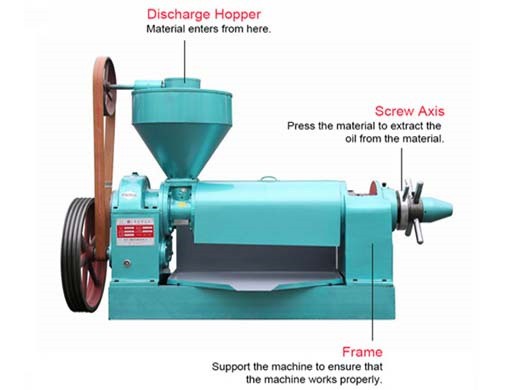

Vegetable oil processing is a complicated oil processing process.For different oil seeds the production process is diffent too. Vegetable oils are being processed by grinding, cooking, expelling and pressing, or by solvent extraction of the raw materials.

: Basics of Alkali Refining of Vegetable Oils : Pdf : Renato Dorsa, Klaus-Peter Eickhoff 1. Removal of undesired products from crude oils •free Removal of undesired products from crude oils •free Basics of Alkali Refining of Vegetable Oils (Alkali Rafinasyon)

Fat and oil processing chemistry Britannica

Fat and oil processing, method by which animal and plant substances are prepared for eating by humans. More than 90 percent of the world production of fats and oils is used in edible products, and the objective of most processing steps is to convert crude fats of low palatability or undesirable

Get Price

Acid oils from chemical refining for feed FEDIOL

acid oils are. 1) For removal of free fatty acids, vegetable oil refining traditionally consists of an alkali treatment step followed by vacuum distillation (“deodorization”). This renders as by-products acid oils and deodistillates. Such type of refining is often referred to as chemical refining.

Get Price

Basics of Alkali Refining & Water Washing of Vegetable

Basics of Alkali Refining & Water Washing of Vegetable Oils ( Andrew Logan ) Purpose of Alkali Refining • Removing of impurities from oil Phospholipids (gums) Colour bodies Metal Ions Pro-oxidants • Iron • Copper Free Fatty Acids Solids meal fines Oil Impurities • Phospholipids cause emulsions darken oil with heat interfere with crystallization

Get Price

Refining of Edible oils: Edible Oil Processing

Edible Oil Processing ALKALI REFINING 1. Introduction. Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Figure 1). The names physical and chemical refining come from the process technology used to remove the Free

Get Price

Reducing Oil Losses in Alkali Refining SpringerLink

Thus, alkali neutralization causes a major loss of neutral oil in the chemical refining of edible oils. The effects of demulsifiers (NaCl, KCl, Na 2 SO 4 and tannic acid) on reducing alkali refining losses of refined palm, soybean, and sunflower oils (used as model oils) incorporated with FFA from rice bran oil were investigated.

Get Price

Chemical Refining and Physical Refining of Vegetable Oil

Edible/vegetable oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire oil refining plant process comprises degumming/neutralization, bleaching, deodorization, and winterization.

Get Price

Refining process of fat and oil

PHYSICAL REFINING The Physical Refining process is used for oils and fats with high FFA and contains three basic steps: Acid Conditioning or Enhanced Degumming Bleaching Stripping and Deodorizing The degumming process used depends on the oil or fat being refined. Methods of Refining CHEMICAL REFINING The Chemical Refining process is used for

Get Price

Oil+refining-2 alfalaval Basics of Alkali

View Notes Oil+refining-2 from CHEMICAL E 160 at University of California, Berkeley. alfalaval Basics of Alkali Refining & Water Washing of Vegetable Oils Andrew Logan Alfa Laval Copenhagen

Get Price

Basics of alkali refining Soap Oil Refinery

Basics of alkali refining Free download as File (.pdf), Text File (.txt) or view presentation slides online. Basics of alkali refining

Get Price

Understanding Oils & Fats and Processing aspects in practice

Understanding Oils & Fats and Processing aspects in practice LOTTE FOODS Kim Jong Gil. Agenda 1. What is Oils & Fats ? 2. Edible Oil Processing 3. TransFatty Acids 4. Latest Technologies Adopted in Lotte Foods DIC Vacuum Production and Nanoneutralization in Refining Process Environmentally Friendly Energy Saving in Plant Management. What is Oils & Fats? Definition of Oils & Fats: 油(Oil

Get Price

Refining of Edible oils: Edible Oil Processing

Conventionally these oils were refined by alkali refining. The drawback of the alkali refining process is the entrainment of significant quantities of neutral oil with the soap stock resulting in a loss of yield. Additional costs are incurred by the soap stock splitting and effluent treatment.

Get Price

9.11.1 Vegetable Oil Processing US EPA

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn germ, cottonseed, and soybean), and other mills. Wet corn germ mills are the primary producers of corn germ oil. Approximately 137 vegetable oil plants operate in the United States.

Get Price

Chemical and Physical Effects of Processing Fats and Oils1

vegetable oils, i.e., margarines and shortenings. These factors have lead to development of technological processes for treatment of crude oils to make them as bland and colorless as possible and for modification of the physical characteristics of the oils. The refining techniques consist of water or acid degumming, alkali refining, bleaching and

Get Price

Refining FEDIOL

The purpose of refining edible oils and fats is to remove free fatty acids and other objectionable substances including impurities while maintaining the nutritional value and ensuring the quality and stability of the end product. FEDIOL has developed a Code of Practice for refining vegetable oils (link), on which the description below is based.This process consistently yields safe products.

Get Price

C.M.Bernardini Oils & Fats Refining

Fats and oils are marketed with a cold stability temperature determined by a cold test. To comply with such standard, certain vegetable oils require a winterizing process consisting in precipitating as crystals, under programmed conditions of temperature and time, the saturated glycerides or waxes, which cause them to become cloudy.

Get Price

Processing of Soybean Oil for Food Uses

removed from the oil by waterdegumming (12). Although most of the remaining phosphatides are removed during alkali refining, vegetable oils often contain some phosphatides that are not removed by hydration. Most commercially produced oils will contain less than 5 ppm phosphorus. Refining. Refining of vegetable oils is practiced to remove free

Get Price

alfalaval

Basics of Alkali Refining & Water Washing of Vegetable Oils Andrew Logan Alfa Laval Copenhagen A/S. alfalaval Alkali Refining & Washing Alkali Refining & Washing Special Degumming Special Degumming Water Degumming Water Degumming Gums drying Gums drying Soapstock splitting Soapstock splitting DewaxingDewaxing DewaxingDewaxing BleachingBleaching BleachingBleaching

Get Price

Use of Soluble Silicates in Vegetable Oil Refining to

Use of Soluble Silicates in Vegetable Oil Refining to Remove Acidity and Soapstock by Filtration and Refining. Ernesto Hernandez. Texas A&M University, College Station, TX, USA. Use of sodium silicate in refining of several vegetable oils is reported as method to replace conventional processing with caustic refining. The method used to remove the

Get Price

Refining biofeedstock innovations Honeywell UOP

Refining biofeedstock innovations Analysis of processing routes for producing renewable diesel, gasoline and olefins with feedstocks that include vegetable oil, pyrolysis oil and biomass. Biorenewable integration in refineries is evaluated along with work to commercially produce green diesel T he production of renewable fuels has been expanding worldwide, driven by increasing petroleum prices

Get Price

Oil refinery(degumming process)

1. OIL REFINERY ‘Degumming Process’ By : Izyan Hanis Bt Ramlan Nor Adilah Bt Sazali Mursyidah Bt Abdul Gani Liyana Bt Jamil 2. Refining of crude oil • Crude oils as received from the extraction plant contain several non-triglyceride components which must be removed. • Refining consists of several processes which accomplish this aim

Get Price

How cooking oil is made material, manufacture, making

Cooking oil consists of edible vegetable oils derived from olives, peanuts, and safflowers, to name just a few of the many plants that are used. Liquid at room temperature, cooking oils are sometimes added during the preparation of processed foods. They are also used to fry foods and to make salad dressing.

Get Price