oil processing steps edible oil refining oil extraction in Daman

Chapter 5 : Processing and refining edible oils

Chapter 5 : Processing and refining edible oils. Contents Previous Next. Rural vegetable oil production In oil extraction, milled seed is mixed with hot water and boiled to allow the oil to float and be skimmed off. Palm is sterilized as a first step in processing. Adipose tissues and fish-based raw materials (that is, the body or

Processing of edible oils is often broken into the three RBD categories: refining, bleaching and deodorizing. Each of these steps used in large scale processing may be duplicated on a smaller scale. Some are more difficult to implement on a small scale, and may not be justified depending on the market for the end product.

Cold-Pressed Oils & Refining Oils Methods Of Extraction

Since 1950s, manufacturers also started using refining process for groundnut, sesame, coconut, etc. Refined oil extraction has higher oil yield. For example, in cold pressed method we need 2.5kg of groundnuts to make 1 litre of groundnut oil. The refined process will extract 1 litre of oil from 2.2 kg of groundnuts.

The oil refinery process is largely dependent on the type of seed from which the oil is being extracted, and whether the final product will be edible or not. Most of the refining process that takes place in oil milling plants is that of edible oil, which makes it important for plant owners to know the steps involved. Crude oil that is refined to become edible oil is taken from oil mills as

9.11.1 Vegetable Oil Processing

soybean processing, except for differences in the soybean preparation for oil extraction. The process for soybeans typically consists of five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining.

edible oils that can be used in food applications after refining. Based on seed crushing and solvent extraction, the process can be applied to a wide range of feedstocks, without modifying the internals of the extractor. The Lurgi extractor has superior processing efficiency in oil extraction

Edible oil refining SlideShare

Miscella refining: The refining of crude oil in the solvent extraction plant, prior to solvent stripping, is termed miscella refining. Miscella refining has been applied to a variety of oils, including cottonseed, soybean, sunflower, palm, coconut and tallow.

Edible oil refining process flow chart. This edible oil refining process flow chart is made based on the design of DOING engineer. It is chemical edible oil refining process flow chart. The whole process consists of four steps: degumming, deacidification, decolorization and deodorization.

Steps in the oil refinery process Oil Refinery Plant

The oil refinery process is largely dependent on the type of seed from which the oil is being extracted, and whether the final product will be edible or not. Most of the refining process that takes place in oil milling plants is that of edible oil, which makes it important for plant owners to know the steps involved. Crude oil that is refined to become edible oil is taken from oil mills as

Edible oil refining process is vital for oil mill plant to produce pure and quality edible oil. Main processing steps are bleaching, degumming, deodorizing.

5 Key Steps in Refining of Edible Oil Blogging Hub

The dewaxing process is recommended for edible oils that show turbid characteristics below 5 degree Celsius. Some of the edible oils that are put through the winterization process are cotton and sunflower seed oil. In the winterization process, the edible oil is mixed with a crystallizing agent and then run through a static mixer.

Get Price

9.11.1 Vegetable Oil Processing

soybean processing, except for differences in the soybean preparation for oil extraction. The process for soybeans typically consists of five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining.

Get Price

EXTRACTION AND REFINING Air Liquide

edible oils that can be used in food applications after refining. Based on seed crushing and solvent extraction, the process can be applied to a wide range of feedstocks, without modifying the internals of the extractor. The Lurgi extractor has superior processing efficiency in oil extraction

Get Price

Edible Oils & Fats Refining Process Phoenix Equipment

Alfa Laval, Chempro, Silverson, and Zink Hamworthy are major edible oil process equipment manufactures, and Desmet Ballestra is a major technology provider. Conclusions: Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear color, good keeping quality and frying stability.

Get Price

Fat and oil processing Processing of extracted oil

Processing of extracted oil. The extent of processing applied to fats depends on their source, quality, and ultimate use. Many fats are used for edible purposes after only a single processing step—i.e., clarification by settling or filtering. Most cold-pressed oils (for example, cold-pressed olive, peanut, and some coconut and sunflower oils) can be used in food products without further

Get Price

Soybean Oil Refining Process Soybean Oil Refinery Plant

The appropriate flake size needs to be maintained for the better extraction of oil from the raw material. The solvent extracted oil is then refined in the edible oil refinery by following the steps of refining. The refining can be done either by physical route or by chemical route. The soybean oil refining steps are: Degumming Section

Get Price

Processing Contaminants in Edible Oils ScienceDirect

This chapter examines the status of the literature to date as it pertains to the formation pathways of MCPD-FE and G-FE in refined edible oils, considers critical topics, including the most prevalent precursor compounds and detailed formation mechanisms responsible for the generation of these process contaminants during oil production and refining.

Get Price

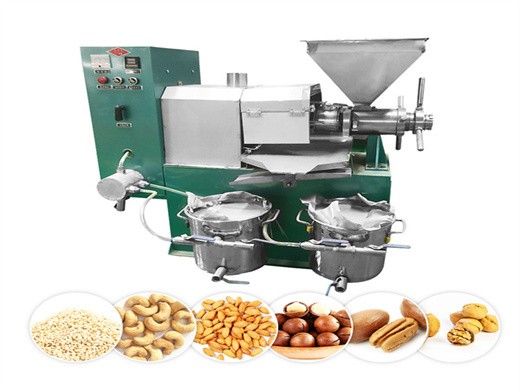

Edible Oil Extraction Machinery, Edible Oil Extraction

A specific oil processing method is applied which includes seed preparation, seed processing, seed conditioning, oil extraction, oil filtering and oil refining. Manufactured as per the latest technology, our edible oil extraction machinery finds a huge scope in the oil extraction sector.For the achievement of extracting optimum quality of oil

Get Price

OIL REFINERY PROCESSES

• Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units. • Step 2 most typical methods of crude-oil desalting are chemical and electrostatic separation,and both use hot water as the extraction agent.

Get Price

edible oil extraction

The edible oil refining process in general comprises of Degumming, Neutralization, Bleaching and Deodorization and Winterisation. Chemical refining is the traditional method whereby the free fatty acid of the crude oils are neutralized with Caustic Soda. The resultant Sodium Soaps are removed by Batch Settling or by means of Centrifugal Separators.

Get Price

Processing and refining edible oils Edible Oil Expeller

In the classic The refining process, this level is mere versed in the neutralisation stage, but special degumming processes may be required for physical refining of high-phosphatide seed oils. these processes rely on improved hydration of phospholipids by intimate contact of the oil with an aqueous solution of citric Acid,Phosphoric acid andlor

Get Price

Steps in the oil refinery process Oil Refinery Plant

The oil refinery process is largely dependent on the type of seed from which the oil is being extracted, and whether the final product will be edible or not. Most of the refining process that takes place in oil milling plants is that of edible oil, which makes it important for plant owners to know the steps involved. Crude oil that is refined to become edible oil is taken from oil mills as

Get Price

Process Description of Edible oil Refining edible oil

The edible oil refining process in general comprises of Degumming, Neutralization, Bleaching and Deodorization and Winterisation. Chemical refining is the traditional method whereby the free fatty acid of the crude oils are neutralized with Caustic Soda. The resultant Sodium Soaps are removed by Batch Settling or by means of Centrifugal Separators.

Get Price

9.11.1 Vegetable Oil Processing

soybean processing, except for differences in the soybean preparation for oil extraction. The process for soybeans typically consists of five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining.

Get Price

Final Vegetable Oil Processing IFC

The EHS Guidelines for Vegetable Oil Processing are applicable to facilities that extract and process oils and fats from vegetable sources. It covers crude oil production and refining processes, from the preparation of raw materials to the bottling and packaging of final products for human or animal consumption, among other uses.

Get Price

Edible Oils & Fats Refining Process Phoenix Equipment

Alfa Laval, Chempro, Silverson, and Zink Hamworthy are major edible oil process equipment manufactures, and Desmet Ballestra is a major technology provider. Conclusions: Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear color, good keeping quality and frying stability.

Get Price

OIL REFINERY PROCESSES

• Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units. • Step 2 most typical methods of crude-oil desalting are chemical and electrostatic separation,and both use hot water as the extraction agent.

Get Price

Alfa Laval Edible oil refining process systems

Our edible oil production process line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route. In the chemical refining route, free fatty acids undergo a reaction to create aqueous

Get Price

hexane solvent extraction plant oil extractor sunflower

Oilseeds crushing De Smet Engineers & Contractors. Oilseeds crushing vegetable oil extraction. De Smet Engineers & Contractors has been involved in all steps of the production of vegetable oils from oilseeds crushing for the construction of Edible Oils Plants; in this article you will find a more detailed understanding about the process of vegetable oil extraction:.

Get Price

Processing Contaminants in Edible Oils ScienceDirect

This chapter examines the status of the literature to date as it pertains to the formation pathways of MCPD-FE and G-FE in refined edible oils, considers critical topics, including the most prevalent precursor compounds and detailed formation mechanisms responsible for the generation of these process contaminants during oil production and refining.

Get Price

Edible Oil Extraction Machinery, Edible Oil Extraction

A specific oil processing method is applied which includes seed preparation, seed processing, seed conditioning, oil extraction, oil filtering and oil refining. Manufactured as per the latest technology, our edible oil extraction machinery finds a huge scope in the oil extraction sector.For the achievement of extracting optimum quality of oil

Get Price

Green Vegetable Oil Processing ScienceDirect

Aqueous oil extraction is a technology with great potential in the oil industry because it offers a number of advantages compared to conventional solvent extraction. This chapter discusses the aqueous extraction process. The aqueous extraction process has already been used successfully and commercially for virgin olive oil and avocado oil

Get Price

Edible Oil Fat Refining IPS ENGINEERING

The Chemistry and Technology of Edible Oils and Fats, Pergamon Press, Oxford 1961. Oilseed Processing Symposium 1976, J. Am. Oil Chem. Soc. 54 (1977) Oilseed Extraction and Meal Processing, presented at the AOCS World Conference in Singapore. Fatty Acid Technology, Technical brochure no. 197e/3.91/30, Lurgi AG, Frankfurt, 1991

Get Price

Edible Oil Refining Processing Line

Five Main Steps of Edible Oil Refining Processing Line: 1. Crude Oil Degumming: In this step gums in crude oil are removed by hydration with the help of phosphoric acid. 2. Neutralization: In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on

Get Price

Edible Oil Refining Processing Line

Five Main Steps of Edible Oil Refining Processing Line: 1. Crude Oil Degumming: In this step gums in crude oil are removed by hydration with the help of phosphoric acid. 2. Neutralization: In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on

Get Price

Oil and Oilseed Processing II Oklahoma State University

There are three major steps in traditional solvent extraction (Figure 1): oil extraction, meal and oil desolventizing, and meal toasting. Figure 1: Simplified flow diagram of a hexane extraction process . In the 1800s, small batch type oil extraction systems were common in Europe.

Get Price

Process of Edible Oil Refining Equipm

With the continuous development of the technology of edible oil refining equipment, currently five or more “continuous” oil refining processes are widely used at and abroad, namely “hydration degumming, alkaline deacidification, adsorption decolorization, winterization dewaxing, and high-temperature deodorization”.

Get Price

Final Vegetable Oil Processing IFC

The EHS Guidelines for Vegetable Oil Processing are applicable to facilities that extract and process oils and fats from vegetable sources. It covers crude oil production and refining processes, from the preparation of raw materials to the bottling and packaging of final products for human or animal consumption, among other uses.

Get Price

Edible Oil Fat Refining IPS ENGINEERING

The Chemistry and Technology of Edible Oils and Fats, Pergamon Press, Oxford 1961. Oilseed Processing Symposium 1976, J. Am. Oil Chem. Soc. 54 (1977) Oilseed Extraction and Meal Processing, presented at the AOCS World Conference in Singapore. Fatty Acid Technology, Technical brochure no. 197e/3.91/30, Lurgi AG, Frankfurt, 1991

Get Price