what are the main functions of each section in vegetable oil refining process

What are the main functions of each section in vegetable

The complete vegetable oil refining process generally has five parts: degumming, deacidification, decolorization, deodorization and dewaxing/fractionation. Like their names, the function of each section in vegetable oil refining process are different. Next, let us to learn more one by one. 1) Degumming section in vegetable oil refining process:

The functions of Vegetable oil refining process: 1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing. 2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate, make the oil lucency 3) Deodorizing section: to remove off the odor components in oil, let the oil have a good smell

What is the vegetable oil refining process? Edible Oil

Process Description of Vegetable Oil Refining is as follows. Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process.Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge.

Refining Workshop View. Hydrogenation Section of Soybean Oil Production (optional): This process will increase the stability of the soybean oil and will make it less liquid. However, this process will create more saturated fats and will reduce the favorable unsaturated fats. In addition, transfats are produced which can cause hearth problems.

Vegetable oil refining, bleaching and deodorizing process

Vegetable oil refining, bleaching and deodorizing process are a complete process for removing different kinds of impurities from crude oil so as to make the crude oil become refined edible oil. About the specific steps, here Doing Company will introduce them for you one by one. 1. The degumming and deacidification of vegetable oil refining process:

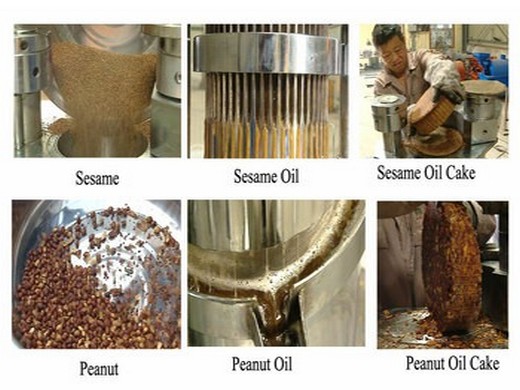

Oil Manufacturing Process. Vegetable oil manufacturing process is a complicated oil manufacturing process.Different raw material has its different processing way, but generally speaking, oils are being processed by grinding, pressing or by solvent extraction and refining of the raw materials.

Chapter 5 : Processing and refining edible oils

Soybean oil, which is high in g-tocopherol and consequently well-protected in vitro, is relatively low in a-tocopherol and cannot reach this ratio. The, b-carotene in palm oil is another valuable component that needs consideration in the refining process. Special processes for retention are being designed.

from receiving oilseeds to refining, in this section. Although the discussion concentrates on soybean oil, differences in the production process for the other major oilseeds are noted. In addition, this section describes oilseeds and hexane, two specialized inputs in the production of vegetable oil. 2.1.1 Production Process

Oil Refining an overview ScienceDirect Topics

During oil refining, both the free and esterified sterols were reduced with total sterol losses ranging between 18% (Ferrari et al., 1996) and 34% (Verleyen et al., 2002b).During the neutralization stage of chemical refining, 20% of the sterols, mostly the free sterols, were lost in the soapstock (Verleyen et al., 2002b).Sterols also can be removed from oil during deodorization.

In this article, the main steps of the refining process are discussed briefly with special reference to the changes in the crude oils and their importance in the production of high-quality oils. For complete information on the different conditions and equipments used in the different steps, a

Vegetable Oil Production: Industry Profile

from receiving oilseeds to refining, in this section. Although the discussion concentrates on soybean oil, differences in the production process for the other major oilseeds are noted. In addition, this section describes oilseeds and hexane, two specialized inputs in the production of vegetable oil. 2.1.1 Production Process

Get Price

The Refining Process How Oil Refining Works HowStuffWorks

This process is called fractional distillation. You basically heat crude oil up, let it vaporize and then condense the vapor. Newer techniques use Chemical processing on some of the fractions to make others, in a process called conversion. Chemical processing, for

Get Price

Edible oil refinery plant and edible oil refining process

Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

Enzymatic Degumming American Oil Chemists' Society

The water wash used to reduce the phosphorus levels in the degummed oil generates additional oil losses (0.2 to 0.3%), due to residual phospholipids and emulsified oil, but the advantage of this process is the possibility to substitute caustic refining as way to prepare the oil for bleaching and physical refining.

Get Price

Optimization of Bleaching Process American Oil Chemists

To arrive at an optimal bleaching process, you must first establish what the primary target specifications will be and make sure that you are getting the appropriate contaminants removed by the overall refining process (see Fig. 1). Good refined oil must be [1] : Low in phosphorus (good if <15 ppm, very good if <10 ppm and excellent if <5 ppm)

Get Price

Hazards Assessment of Vegetable Oil Storage and

4. Analysis of vegetable oil refining 4.1 Process description In order to consider the typical refining process conditions, the purification of a typical sunflower oil was simulated assuming a free fatty acid content (FFAC) of 4 %wt. to be reduced up to 0.04 %wt. A schematization of the process is reported in the PFD shown in Figure 3.

Get Price

Oil Refining an overview ScienceDirect Topics

Box 21.4. Refining Margins Example—Crack Spread 5. Crack spread is a term used in the oil industry and futures trading for the differential between the price of crude oil and petroleum products extracted from it—that is, the profit margin that an oil refinery can expect to make by “cracking” crude oil (breaking its long-chain hydrocarbons into useful shorter-chain petroleum products).

Get Price

Edible oil refining manufacturing in africa_Industry News

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. Main equipment: Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter, Electricity distribution control, Air compressor

Get Price

Introduction to Degumming American Oil Chemists' Society

Since this water degumming process does not remove all phosphatides from the oil, Table 1 does not reflect the composition of the phosphatides present in the crude oil itself. Just as a triglyceride oil is a mixture of triacylglycerols with different fatty acids, each phosphatide is

Get Price

Deodorization an overview ScienceDirect Topics

Deodorization of refined and bleached oil is carried out under vacuum and at an absolute pressure of 1–6 mm of mercury in the United States, depending on the type of vacuum system on the deodorizer. Modern deodorizers in Europe and the United States are operated at 2–3 mm of mercury or even lower vacuum (1 mm) via a special ejector design to be discussed in Chapter 14.

Get Price

9.11.1 Vegetable Oil Processing

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn germ, cottonseed, and soybean), and other mills. Wet corn germ mills are the primary producers of corn germ oil. Approximately 137 vegetable oil plants operate in the United States.

Get Price

Cooking oil refining process,vegetable oil refining

The Cooking oil refining process,vegetable oil refining process machine production cooking oil plant will need approximately 25-30 tons rice bran per day as raw material. The total cost of project may be more or less 1,000,000 USD. The cost of project for 10 tons per day from about 50 tons rice

Get Price

Vegetable oil

Vegetable oils, or vegetable fats, are oils extracted from seeds or from other parts of fruits. Like animal fats, vegetable fats are mixtures of triglycerides. Soybean oil, grape seed oil, and cocoa butter are examples of fats from seeds. Olive oil, palm oil, and rice bran oil are examples of fats from other parts of fruits. In common usage, vegetable oil may refer exclusively to vegetable

Get Price

9.11.1 Vegetable Oil Processing

9.11.1 Vegetable Oil Processing 9.11.1.1 General1-5 The industry group producing fats and oils includes cottonseed oil mills, soybean oil mills, vegetable oil mills (other than corn germ, cottonseed, and soybean), and other mills. Wet corn germ mills are the primary producers of corn germ oil. Approximately 137 vegetable oil plants operate in the United States.

Get Price

The Refining Process How Oil Refining Works HowStuffWorks

This process is called fractional distillation. You basically heat crude oil up, let it vaporize and then condense the vapor. Newer techniques use Chemical processing on some of the fractions to make others, in a process called conversion. Chemical processing, for

Get Price

Edible oil refinery plant and edible oil refining process

Edible oil refinery plant and edible oil refining process . Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Get Price

Degumming an overview ScienceDirect Topics

Monoj K. Gupta, in Practical Guide to Vegetable Oil Processing (Second Edition), 2024 4.4.5.5 Real Benefit of Enzymatic Degumming Process. Enzymatic degumming process is superior to the chemical degumming process as described at the beginning of this section. This will be more evident with the following example. Soybeans from some of the Latin American countries arrive with very high FFA and

Get Price

Vegetable oil

Vegetable oils, or vegetable fats, are oils extracted from seeds or from other parts of fruits. Like animal fats, vegetable fats are mixtures of triglycerides. Soybean oil, grape seed oil, and cocoa butter are examples of fats from seeds. Olive oil, palm oil, and rice bran oil are examples of fats from other parts of fruits. In common usage, vegetable oil may refer exclusively to vegetable

Get Price

The process of crude oil refining EME 801: Energy

The process of crude oil refining Once crude oil is extracted from the ground, it must be transported and refined into petroleum products that have any value. Those products must then be transported to end-use consumers or retailers (like gasoline stations or the company that delivers heating oil to your house, if you have an oil furnace).

Get Price

Edible oil refining manufacturing in africa_Industry News

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. Main equipment: Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter, Electricity distribution control, Air compressor

Get Price

Introduction to Degumming American Oil Chemists' Society

Since this water degumming process does not remove all phosphatides from the oil, Table 1 does not reflect the composition of the phosphatides present in the crude oil itself. Just as a triglyceride oil is a mixture of triacylglycerols with different fatty acids, each phosphatide is

Get Price

Lecture 3: Petroleum Refining Overview

prominent process technology in process engineering. 3.1 Crude oil Crude oil is a multicomponent mixture consisting of more than 108 compounds. Petroleum refining refers to the separation as well as reactive processes to yield various valuable products. Therefore, a key issue in the petroleum refining is to deal with multicomponent feed streams

Get Price

Deodorization an overview ScienceDirect Topics

Deodorization of refined and bleached oil is carried out under vacuum and at an absolute pressure of 1–6 mm of mercury in the United States, depending on the type of vacuum system on the deodorizer. Modern deodorizers in Europe and the United States are operated at 2–3 mm of mercury or even lower vacuum (1 mm) via a special ejector design to be discussed in Chapter 14.

Get Price

Factory Price Supply Cooking Oil Refining Machine,Edible

What's the functions of Vegetable oil refining process? (1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing. (2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate, make the oil lucency

Get Price

Coconut Oil: Chemistry, Production and Its

Coconut oil is an edible oil that has been consumed in tropical countries for thousands of years (Gopala et al., 2010) [14] . Over the last decade, the world production of coconut oil has been

Get Price

The status of industrial vegetable oils from genetically

vegetable oil to form methyl esters that can be used directly or blended with other fuels in the process by which DNA (or occasionally a phospholipid-rich fraction obtained during the refining of vegetable oils that has many uses as an emulsifier in a wide range of processed foods.

Get Price

Emission Factor Documentation for AP-42 Vegetable Oil

of vegetable oil. Over the last 2 to 3 years, approximately 1.1 billion to 1.3 billion bushels of soybeans were processed each year. Other major vegetable oils are cottonseed, peanut, and corn germ. In 1995 there were 86 soybean processing plants, 32 cottonseed oil mills, and 19 vegetable oil mills except corn germ, cottonseed, and soybean.

Get Price

Degumming an overview ScienceDirect Topics

Monoj K. Gupta, in Practical Guide to Vegetable Oil Processing (Second Edition), 2024 4.4.5.5 Real Benefit of Enzymatic Degumming Process. Enzymatic degumming process is superior to the chemical degumming process as described at the beginning of this section. This will be more evident with the following example. Soybeans from some of the Latin American countries arrive with very high FFA and

Get Price

Edible oil refining manufacturing in africa_Industry News

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. Main equipment: Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter, Electricity distribution control, Air compressor

Get Price