Russia cooking oil refining process

Oil Refining in Russia Downstream Operating Results

Refinery throughput at the Company’s mini-refineries in Russia amounted to 1.9 mmt in 2024, with Nizhnevartovsk Oil Refining Association accounting for a majority 1.5 mmt of the oil refined. In 2024, the Company’s oil refining activities were focused on:

There is a refining plant and deodorization plant at the facilities which allow obtaining high-quality vegetable fats. The refining plant makes it possible to process up to 280 tons of vegetable oil per day. Oil undergoes all stages of refining: Hydration; Russia,

Oil Refining Industry in Russia 2024 Research and Markets

The downstream energy sector report, “Oil Refining Industry in Russia” is a complete source of information on Russia crude oil refining industry. It provides refinery level information relating to existing and planned (new build) refineries such as insights and forecasts of refinery capacities, refined petroleum products production and

LUKOIL Group integrates four refineries in Russia (in Perm, Volgograd, Nizhny Novgorod, and Ukhta), along with three refineries in Europe (in Italy, Romania, and Bulgaria), and has a 45% interest in a refinery in the Netherlands. The aggregate capacity of these refineries is 84.6 million tonnes, almost as much as the Company's total oil production in 2024. The Company's plants have cutting

BASICS OIL REFINING

Current refining process introduced in 1900 Introduction of refining due to: • Use of coconut oil for margarine • Decolouring of cottonseed oil • Changing taste • Removal of catalyst poisons before hydrogenation. • Removal of solvents from extracted oils GD

Our edible oil production process line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route. In the chemical refining

OIL REFINERY PROCESSES

• Crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. • Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

The first automobile gasoline at the Ryazan refinery (as was the name of the enterprise until July 2002) was received on October 19, 1960. This day is considered the birthday of the plant. Today, JSC RORC is one of the leaders in the Russian oil refining industry.

Coking FSC 432: Petroleum Refining

Coking is the most severe thermal process used in the refinery to treat the very bottom-of-the-barrel of crude oil, i.e., vacuum residue. Because of the high severity of thermal cracking during coking, the residue feed is completely converted to gas, light and medium distillates, and coke with no production of residual oil.

Edible Oil Refinery Technology. The objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. Methods of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.

Reprocessing of Used Cooking Oil

ACID OIL. Acid oil, which is a by-product in vegetable oil refining, mainly contains free fatty acids (FFAs) and acylglycerols. Acid oil also contains 1 to 2% phospholipids, 8 to 10% sterols and 5

Get Price

How cooking oil is made material, manufacture, making

People in many regions began to process vegetable oils thousands of years ago, utilizing whatever food stuffs they had on to obtain oils for a variety of cooking purposes. Early peoples learned to use the sun, a fire, or an oven to heat oily plant products until the plants exuded oil that could then be collected.

Get Price

Process Flow Diagrams REFINERY PROCESS

REFINERY— PROCESS FLOW DIAGRAMS 5 Process Flow Diagrams — Refinery Conversion Process — Typical Distillation Unit Process Desciptions One of the other feedstocks to a refinery is hydrogen, which can be used in a hydrotreater, isomerization, FCC, reformer, and a

Get Price

BASICS OIL REFINING

Current refining process introduced in 1900 Introduction of refining due to: • Use of coconut oil for margarine • Decolouring of cottonseed oil • Changing taste • Removal of catalyst poisons before hydrogenation. • Removal of solvents from extracted oils GD

Get Price

Refining Vegetable Oil: A Nasty Process

The process of refining vegetable oil damages the fats and makes the oils very unstable and prone to going rancid quite easily. Rancid oils in any form are particularly bad for your health because they introduce cancer-causing free radicals into your body, without

Get Price

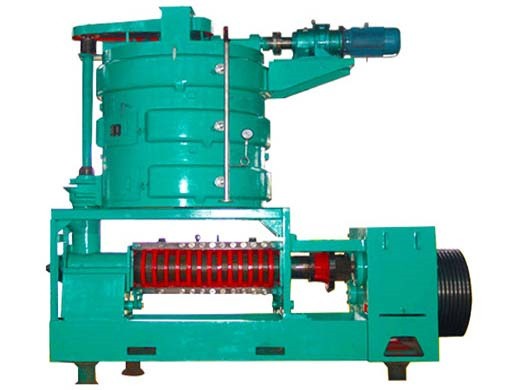

How to set up a cooking oil refinery plant with small

Batch type cooking oil refinery plant 3D picture. So, if you want to set up a cooking oil refinery plant with small budget, the batch type cooking oil refinery plant is your best choice, which can be customized into 1-20 tons per day. Although the batch type cooking oil refinery plant cost is low, the quality of product oil can be guaranteed.

Get Price

rusoil

The heart of our business is the oil refining along with supply and trading of crude oil and refined oil products. Nasneft has simultaneously grown a network of strategic assets such as refineries, storage's and tank’s facilities, that enable optimization of supply chain efficiency.

Get Price

OIL REFINERY PROCESSES

• Crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. • Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

Get Price

BASICS OIL REFINING

Current refining process introduced in 1900 Introduction of refining due to: • Use of coconut oil for margarine • Decolouring of cottonseed oil • Changing taste • Removal of catalyst poisons before hydrogenation. • Removal of solvents from extracted oils GD

Get Price

Ryazan Oil Refining Company

The first automobile gasoline at the Ryazan refinery (as was the name of the enterprise until July 2002) was received on October 19, 1960. This day is considered the birthday of the plant. Today, JSC RORC is one of the leaders in the Russian oil refining industry.

Get Price

Refining Process Edible Oil Production

REFINING PROCESS. Chemical refining, also known as caustic and alkali processes used in refining system. Process steps; degumming, neutralization, bleaching, winterization and, deodorization. The aim of refining is to remove that phospholipids, gums, free fatty acids, metal and soaps, high temperature melting components present in small quantities, volatile compounds (mainly ketones and

Get Price

Reprocessing of Used Cooking Oil

ACID OIL. Acid oil, which is a by-product in vegetable oil refining, mainly contains free fatty acids (FFAs) and acylglycerols. Acid oil also contains 1 to 2% phospholipids, 8 to 10% sterols and 5

Get Price

5 Key Steps in Refining of Edible Oil Blogging Hub

A safer way to bring expediency in refining process is following standard refining process that is distributed in 5 stages. Let’s look at the edible oil refining process in detail. 1. Degumming. It is the first stage of the refining process that works to remove impurities (especially phosphatides which are called gums) of the cooking oil.

Get Price

Chapter 5 : Processing and refining edible oils

Soybean oil, which is high in g-tocopherol and consequently well-protected in vitro, is relatively low in a-tocopherol and cannot reach this ratio. The, b-carotene in palm oil is another valuable component that needs consideration in the refining process. Special processes for retention are being designed.

Get Price

Process Flow Diagrams REFINERY PROCESS

REFINERY— PROCESS FLOW DIAGRAMS 5 Process Flow Diagrams — Refinery Conversion Process — Typical Distillation Unit Process Desciptions One of the other feedstocks to a refinery is hydrogen, which can be used in a hydrotreater, isomerization, FCC, reformer, and a

Get Price

Refining Vegetable Oil: A Nasty Process

The process of refining vegetable oil damages the fats and makes the oils very unstable and prone to going rancid quite easily. Rancid oils in any form are particularly bad for your health because they introduce cancer-causing free radicals into your body, without

Get Price

How cooking oil is made material, manufacture, making

People in many regions began to process vegetable oils thousands of years ago, utilizing whatever food stuffs they had on to obtain oils for a variety of cooking purposes. Early peoples learned to use the sun, a fire, or an oven to heat oily plant products until the plants exuded oil that could then be collected.

Get Price

rusoil

The heart of our business is the oil refining along with supply and trading of crude oil and refined oil products. Nasneft has simultaneously grown a network of strategic assets such as refineries, storage's and tank’s facilities, that enable optimization of supply chain efficiency.

Get Price

How to set up a cooking oil refinery plant with small

Batch type cooking oil refinery plant 3D picture. So, if you want to set up a cooking oil refinery plant with small budget, the batch type cooking oil refinery plant is your best choice, which can be customized into 1-20 tons per day. Although the batch type cooking oil refinery plant cost is low, the quality of product oil can be guaranteed.

Get Price

Cottonseed Oil Manufacturing Process and Machinery

Oil Refining: Since the crude cottonseed oil contains high content of gossypol, it needed to be refined to improve the quality and ensure the final refined cottonseed oil is completely safe for eating. The general refining process in cottonseed oil mills is degumming, deacification, decolorizing, deordorizing, and

Get Price

About Sinoder oil refineries,oil refinery plants

3) Plant Oil Leaching, 3-1000t/D 4) Continuous And Semi-Continuous Salad Oil Physical Refining, 10--600t/D 5) Senior Cooking Oil Refining, 1t/D-1000T/D 6) Cottonseed Dephenolizing Protein, 50--500t/D 7) Oil Fractionation, 5--600t/D 8) corn germ Oil, Rice Bran Oil, Sunflower Oil Winterization Dewaxing Production Line, 5--300t/D

Get Price

BASICS OIL REFINING

Current refining process introduced in 1900 Introduction of refining due to: • Use of coconut oil for margarine • Decolouring of cottonseed oil • Changing taste • Removal of catalyst poisons before hydrogenation. • Removal of solvents from extracted oils GD

Get Price

OIL REFINERY PROCESSES

• Crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. • Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

Get Price

5 Key Steps in Refining of Edible Oil Blogging Hub

A safer way to bring expediency in refining process is following standard refining process that is distributed in 5 stages. Let’s look at the edible oil refining process in detail. 1. Degumming. It is the first stage of the refining process that works to remove impurities (especially phosphatides which are called gums) of the cooking oil.

Get Price

Refining Process Edible Oil Production

REFINING PROCESS. Chemical refining, also known as caustic and alkali processes used in refining system. Process steps; degumming, neutralization, bleaching, winterization and, deodorization. The aim of refining is to remove that phospholipids, gums, free fatty acids, metal and soaps, high temperature melting components present in small quantities, volatile compounds (mainly ketones and

Get Price

Reprocessing of Used Cooking Oil

ACID OIL. Acid oil, which is a by-product in vegetable oil refining, mainly contains free fatty acids (FFAs) and acylglycerols. Acid oil also contains 1 to 2% phospholipids, 8 to 10% sterols and 5

Get Price

Chapter 5 : Processing and refining edible oils

Soybean oil, which is high in g-tocopherol and consequently well-protected in vitro, is relatively low in a-tocopherol and cannot reach this ratio. The, b-carotene in palm oil is another valuable component that needs consideration in the refining process. Special processes for retention are being designed.

Get Price