cottonseed oil refinery plant cottonseed oil refinery in Ecuador

Cotton Seed Oil Refinery, खाद्य तेल के संयंत्र Mitsun

We are the leading manufacturer of the Cotton Oil Refinery.. Other details: Degumming & Neutralizing: Crude oil is delivered to the system by the Feed Pump. It is heated to 60 70 C in the Crude Oil pass through plate heat exchanger by hot oil from down-stream

Cottonseed Oil Refining Plant. Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

Set up a Cottonseed oil refinery plant with low cost

Cottonseed oil refinery plant is a necessary part of cottonseed oil mill plant. Because crude cottonseed oil cannot be directly used by human if without any farther refining process. Cottonseed oil is extracted from cottonseeds, whose fatty acid profile generally consists of 70% unsaturated fatty acids and 26% saturated fatty acids.

The deodorization tower used in continuous cottonseed oil refinery plant. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Cotton Seed Oil Refinery, खाद्य तेल के संयंत्र Mitsun

We are the leading manufacturer of the Cotton Oil Refinery.. Other details: Degumming & Neutralizing: Crude oil is delivered to the system by the Feed Pump. It is heated to 60 70 C in the Crude Oil pass through plate heat exchanger by hot oil from down-stream

Cottonseed Oil Refining Plant. Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

Set up a Cottonseed oil refinery plant with low cost

Cottonseed oil refinery plant is a necessary part of cottonseed oil mill plant. Because crude cottonseed oil cannot be directly used by human if without any farther refining process. Cottonseed oil is extracted from cottonseeds, whose fatty acid profile generally consists of 70% unsaturated fatty acids and 26% saturated fatty acids.

Manufacturer & Exporter Of cottonseed oil mill machinery, oil extraction plant and oil refinery plant 2 3. INTRODUCTION Cotton, the single largest natural source of fibre worldwide and one of the most important commercial crops of India, plays

Cottonseed oil plant project built in Uzbekistan__Cooking

Cottonseed oil plant we have installed. Cottonseed oil plant project was installed in Uzbekistan; this cottonseed oil plant project can process raw cottonseed to refined cooking cottonseed oil directly; this is a whole project for producing cotton oil from cotton seed.

Cotton Oil Extraction Plant. Cottonseed Oil Refining; Both the pressed cottonseed oil and the extracted cottonseed oil need to be transported to the oil refinery plant for further treatment. The purpose of cottonseed oil refining is to remove the gum soluble impurities, free fatty acid, pigment, peculiar smell and other impurities in cottonseed

Improvement of the Process of Cottonseed Oil Refining

Cottonseed oil refining was carried out in laboratory. We used crude cottonseed oil having acid value of 10 and 5 mg KOH/g oil. The acid number is a common parameter in the specification of fats and oils. It is defined as the mg of KOH required to neutralize the fatty acids present in 1g of oil [9, 10]. This indicates the degree of purity

Get Price

Cottonseed Oil Extraction Machine/Cottonseed Oil Mill

Cottonseed oil refining process: Cottonseed oil refining machine adopts continuous oil refining process line including unique degumming, deacidification, decolorization, negative blenching, high vacuum steam ejection deodorization,dewaxing, filtering and fully automatic control system, ensuring the most advanced cottonseed oil refining quality

Get Price

Cottonseed Oil Manufacturing Process and Machinery

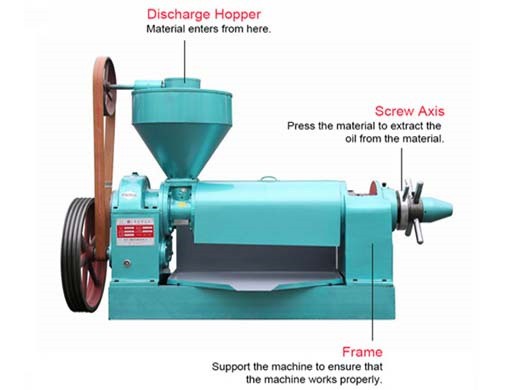

The general refining process in cottonseed oil mills is degumming, deacification, decolorizing, deordorizing, and fractionation. What Equipment Needed for Cottonseed Oil Manufacturing? One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple

Get Price

Manufacturer, supplier of Cottonseed oil processing

Complete set cottonseed oil processing machine are generally divided into three processes, They are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant.Here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

Get Price

Cottonseed Oil Refining Plant ABC Mach

If you are planning to set up a cottonseed oil refining plant or oil refinery equipment for other oilseeds, you are in the right place!. We take the opportunity to intoduce Machinery, an ISO 9001 Company, a leading oil mill engineering firm, established in 1997, specialist in vegetable oil extraction and refinery

Get Price

Cottonseed Oil Extraction Plant, Cottonseed Oil Plant

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock.

Get Price

Cotton Seed Oil Mill Project Report

Cottonseed Oil Refining Plant. Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

Get Price

Cottonseed Oil Press Machine Cotton Seeds Oil Refinery

3.Cottonseed oil Refinery Plant : A.Flow chart: Degumming →Deacidification →Decoloration → Deodorization →edible oil B. Points for cottonseed oil refining plant ♦ Cottonseed oil refinery can be divided into batch refining (<20t/d), semi-continuous refining (20-50 t/d) and continuous refining (>50 t/d) depending on capacity.

Get Price

Cottonseed Oil Mill Plant SlideShare

Manufacturer & Exporter Of cottonseed oil mill machinery, oil extraction plant and oil refinery plant 2 3. INTRODUCTION Cotton, the single largest natural source of fibre worldwide and one of the most important commercial crops of India, plays

Get Price

Complete Cotton Seed Oil Processing Plant Build Oil Mill

Cotton Oil Extraction Plant. Cottonseed Oil Refining; Both the pressed cottonseed oil and the extracted cottonseed oil need to be transported to the oil refinery plant for further treatment. The purpose of cottonseed oil refining is to remove the gum soluble impurities, free fatty acid, pigment, peculiar smell and other impurities in cottonseed

Get Price

Cottonseed Oil Extraction Plant, Cottonseed Oil Plant

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock.

Get Price

Improvement of the Process of Cottonseed Oil Refining

Cottonseed oil refining was carried out in laboratory. We used crude cottonseed oil having acid value of 10 and 5 mg KOH/g oil. The acid number is a common parameter in the specification of fats and oils. It is defined as the mg of KOH required to neutralize the fatty acids present in 1g of oil [9, 10]. This indicates the degree of purity

Get Price

Manufacturer, supplier of Cottonseed oil processing

Complete set cottonseed oil processing machine are generally divided into three processes, They are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant.Here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

Get Price

Cottonseed Oil Manufacturing Process and Machinery

The general refining process in cottonseed oil mills is degumming, deacification, decolorizing, deordorizing, and fractionation. What Equipment Needed for Cottonseed Oil Manufacturing? One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple

Get Price

Basics of Alkali Refining of Vegetable Oils

Alkali Refining: Plant Design Crude oil dosation The capacity of the plant is adjusted by a speed controlled crude oil pump in combination with a massflowmeter. A pre-strainer is installed to protect the pump and following equipment . The oil temperature is adjusted with a heat exchanger by means of steam. Dual pre-strainer Massflow meter Crude

Get Price

Cottonseed Oil Refining Plant ABC Mach

If you are planning to set up a cottonseed oil refining plant or oil refinery equipment for other oilseeds, you are in the right place!. We take the opportunity to intoduce Machinery, an ISO 9001 Company, a leading oil mill engineering firm, established in 1997, specialist in vegetable oil extraction and refinery

Get Price

Cottonseed Oil Extraction Plant Edible Oil Expeller

Introduction to Cottonseed Oil Extraction Plant Cottonseed oil extraction plant adopts solvent extraction method to extract cottonseed oil.The cottonseed oil plant includes cottonseeds pretreatment and prepressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery plant. The residual oil rate in the cottonseed meal is lower than 1%.

Get Price

manufacturer & sale Cottonseed oil extraction plant

Cottonseed oil refinery of cottonseed oil extrction plant: After getting crude cottonseed oil from pretreatment section and extraction section, crude cottonseed oil enters refinery section. There are three main parts in cottonseed oil refinery plant. . a. Deacidification part: It is used to move the acid in the crude oil. b. Decolorization part: The white clay is used to move the color of the

Get Price

cottonseed oil refining plant machinery,cottonseed oil

The cottonseed oil refining plant machinery,cottonseed oil refinery workshop machine,cotton oil refining equipment will need approximately 25-30 tons rice bran per day as raw material. The total cost of project may be more or less 1,000,000 USD.

Get Price

Cottonseed Oil Mill Plant SlideShare

Manufacturer & Exporter Of cottonseed oil mill machinery, oil extraction plant and oil refinery plant 2 3. INTRODUCTION Cotton, the single largest natural source of fibre worldwide and one of the most important commercial crops of India, plays

Get Price

Cottonseed oil production- provides cottonseed oil plant

3.Cottonseed oil Refinery : A.Flow chart: Degumming →Deacidification →Decoloration → Deodorization →edible oil B. Points for cottonseed oil refining plant ♦ Cottonseed oil refinery can be divided into batch refining (<20t/d), semi-continuous refining (20-50 t/d) and continuous refining (>50 t/d) depending on capacity.

Get Price

Cottonseed Oil Extraction Plant Edible Oil Expeller

Introduction to Cottonseed Oil Extraction Plant Cottonseed oil extraction plant adopts solvent extraction method to extract cottonseed oil.The cottonseed oil plant includes cottonseeds pretreatment and prepressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery plant. The residual oil rate in the cottonseed meal is lower than 1%.

Get Price

cottonseed oil refining plant machinery,cottonseed oil

The cottonseed oil refining plant machinery,cottonseed oil refinery workshop machine,cotton oil refining equipment will need approximately 25-30 tons rice bran per day as raw material. The total cost of project may be more or less 1,000,000 USD.

Get Price

Improvement of the Process of Cottonseed Oil Refining

Cottonseed oil refining was carried out in laboratory. We used crude cottonseed oil having acid value of 10 and 5 mg KOH/g oil. The acid number is a common parameter in the specification of fats and oils. It is defined as the mg of KOH required to neutralize the fatty acids present in 1g of oil [9, 10]. This indicates the degree of purity

Get Price

PPT Cottonseed Oil Mill Plant PowerPoint presentation

Title: Cottonseed Oil Mill Plant 1 COTTONSEED OIL MILLPLANT PROCESS 2 GOYUM! Manufacturer Exporter ; Of cottonseed oil mill machinery, oil extraction plant and oil refinery plant ; 3 INTRODUCTION. Cotton, the single largest natural source of fibre worldwide and one of the most important commercial crops of India, plays a dominant role

Get Price

Cottonseed Oil Manufacturing Process and Machinery

The general refining process in cottonseed oil mills is degumming, deacification, decolorizing, deordorizing, and fractionation. What Equipment Needed for Cottonseed Oil Manufacturing? One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple

Get Price

Flowchart of Process for Cottonseed Oil Production

We are your reliable manufacturer of cottonseed oil manufacturing plant. Quality, technology and service are three things that we always focus on as our commitment. Our Best Machinery gathers professional cooking oil processing professors and we can deal with any questions on oil production machinery design, manufacture and oil mill plant

Get Price

Cottonseed Oil Processing Equipment Edible Oil Refining

Cottonseed oil processing equipment can also be used for rapeseed, peanut, sesame and other oil crops. The pre-extracted leaching can be used for one-time leaching of certain oil products. With the advancement of science and technology, the upgrading of oil refining equipment has been continuously improved, and the level has also been generally

Get Price

Alfa Laval Neutralization systems

Multi-mix refining process for virtually any oil. Here the crude oil comes into contact with the caustic soda for a short period of time. It then goes through one to two stages of washing. When processing cottonseed oil or low-quality crude fats and oils, a second lye treatment, known as re-refining

Get Price